7 Best Practices for Effective Harness Cable Assembly Sourcing Globally

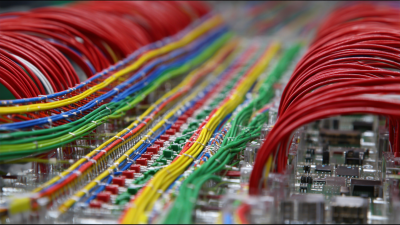

In today's increasingly interconnected world, sourcing harness cable assembly components on a global scale presents both exciting opportunities and unique challenges. As industries evolve and technological advancements accelerate, the need for high-quality, reliable cable assemblies has never been more critical. Effective sourcing practices can significantly impact production efficiency, cost management, and product quality, making it essential for businesses to adopt best practices tailored to harness cable assembly procurement. This blog will explore seven key strategies that can enhance your global sourcing efforts, ensuring you find the right suppliers, maintain excellent quality control, and ultimately drive successful project outcomes. Whether you are a seasoned procurement professional or new to the field, leveraging these insights will help streamline your sourcing process and foster strong supplier relationships.

Understanding Your Harness Cable Assembly Requirements for Global Sourcing

When sourcing harness cable assemblies globally, understanding your specific requirements is crucial to ensuring successful procurement. Start by assessing the technical specifications required for your project, such as the types of materials, environmental conditions, and electrical performance standards. This foundational knowledge will serve as a reference point for potential suppliers, allowing you to identify candidates that can meet your standards. Consideration of industry certifications and compliance will also play a vital role in narrowing down your selection.

Additionally, communication is key in global sourcing. Clearly outline your expectations, delivery timelines, and after-sales support when engaging with suppliers. This will foster transparency and help avoid misunderstandings that can lead to costly delays or quality issues. Establishing a collaborative relationship with your chosen vendors can enable you to gain insights into best practices and innovations in the field, further enhancing the quality and reliability of the harness cable assemblies you procure.

7 Best Practices for Effective Harness Cable Assembly Sourcing Globally

Identifying and Evaluating Potential Suppliers in the Global Market

In the global market, identifying and evaluating potential suppliers for harness cable assembly is crucial for maintaining quality while optimizing costs. According to a report by Research and Markets, the global wiring harness market is projected to grow from $55.6 billion in 2022 to $78.1 billion by 2027, emphasizing the increasing demand for reliable suppliers. Companies must conduct thorough due diligence, reviewing a supplier's financial stability, production capacity, and adherence to industry standards.

Digital tools and platforms have revolutionized supplier evaluation, allowing businesses to access comprehensive analytics and data on supplier performance and reputation. A study by McKinsey highlights that companies employing advanced sourcing analytics can reduce procurement costs by 5-10%. When assessing potential suppliers, organizations should prioritize those with certifications such as ISO 9001 and IATF 16949, which indicate adherence to quality management and automotive manufacturing standards, respectively. By leveraging these practices, companies can ensure they partner with suppliers that not only meet their specifications but also contribute to their long-term operational goals in a competitive global landscape.

7 Best Practices for Effective Harness Cable Assembly Sourcing Globally

| Practice | Description | Importance | Evaluation Criteria |

|---|---|---|---|

| Conduct Thorough Market Research | Analyze global trends, competition, and demand for harness cable assemblies. | Helps in identifying potential regions with competitive advantages. | Market size, growth rate, and competitive landscape. |

| Define Clear Specifications | Outline technical requirements, materials, and performance standards for assemblies. | Ensures suppliers understand the product expectations clearly. | Material types, design drawings, and quality standards. |

| Evaluate Supplier Capabilities | Assess suppliers based on their experience, technology, and production capacity. | Identifies suppliers that can meet production demands. | Years in business, technology used, and maximum output. |

| Check Quality Certifications | Verify suppliers hold necessary quality certifications like ISO. | Ensures compliance with industry standards for quality. | ISO certifications, audit reports, and product testing results. |

| Request Samples and Prototypes | Obtain samples to evaluate design fidelity and build quality. | Allows for practical assessment before mass production. | Sample quality, turnaround time, and sample cost. |

| Assess Communication and Support | Evaluate responsiveness, communication skills, and customer support of suppliers. | Critical for resolving issues and maintaining workflow. | Response times, clarity of communication, and support services. |

| Review Pricing and Terms | Analyze pricing structures and contractual terms offered by suppliers. | Ensures budget alignment and competitiveness of bids. | Pricing models, terms of payment, and minimum order quantities. |

Establishing Clear Communication Channels for Efficient Collaboration

Establishing clear communication channels is paramount for efficient collaboration when sourcing harness cable assemblies globally. Effective communication eliminates misunderstandings that can arise from cultural differences, time zone discrepancies, and language barriers. Utilizing various communication tools—such as video conferencing, instant messaging, and project management software—can help in fostering a more integrated working relationship. Regular check-ins and updates are essential to ensure all parties remain aligned with project goals and timelines, enabling quicker decision-making and problem resolution.

Furthermore, creating a structured communication plan can significantly enhance collaboration. This plan should outline who will communicate what information, the frequency of updates, and preferred communication methods. Encouraging transparency and openness will allow team members to voice concerns and share insights, which can lead to innovative solutions and improved product quality. Ultimately, when all stakeholders feel heard and included, it not only strengthens relationships but also leads to a more streamlined and productive sourcing process.

Implementing Quality Control Measures for Consistent Product Standards

Implementing robust quality control measures is crucial in the global sourcing of harness cable assemblies. According to a report by Grand View Research, the global market for cable assemblies is projected to reach $199.7 billion by 2025, underscoring the immense scale and competitiveness of this industry. With such a significant market, ensuring consistent product standards becomes paramount. Quality control helps to mitigate risks associated with defects, which can lead to costly recalls and damage to brand reputation.

For instance, implementing ISO 9001 certification can streamline processes and foster an environment of continuous improvement.

Incorporating advanced quality assurance techniques such as Six Sigma methodologies can further enhance product consistency. A study published by the Harvard Business Review estimates that companies using Six Sigma significantly reduce their defect rates to below 3.4 defects per million opportunities, which translates into higher customer satisfaction and lower operational costs. Furthermore, utilizing automated inspection technologies, like real-time monitoring systems, enables manufacturers to detect anomalies early in the production process, ensuring that only products that meet stringent quality standards reach the market.

Incorporating advanced quality assurance techniques such as Six Sigma methodologies can further enhance product consistency. A study published by the Harvard Business Review estimates that companies using Six Sigma significantly reduce their defect rates to below 3.4 defects per million opportunities, which translates into higher customer satisfaction and lower operational costs. Furthermore, utilizing automated inspection technologies, like real-time monitoring systems, enables manufacturers to detect anomalies early in the production process, ensuring that only products that meet stringent quality standards reach the market.

Negotiating Terms and Conditions for Successful International Partnerships

When negotiating terms and conditions for successful international partnerships in harness cable assembly sourcing, clarity and mutual understanding are paramount. Start by defining the scope of work and ensuring both parties have a shared vision. This clarity sets the foundation for a fruitful relationship and minimizes misunderstandings that could lead to disputes later on.

Tip: Always include detailed specifications in your contracts to avoid ambiguity. Clearly outline responsibilities, timelines, and quality standards, which can help protect your interests and ensure accountability on both sides.

Additionally, consider the cultural nuances that may impact negotiations. Different countries have various approaches to business dealings, and being sensitive to these differences can aid in building trust. Establishing rapport and demonstrating respect for your partner’s customs can significantly enhance the negotiation process.

Tip: Research potential partners thoroughly before negotiations. Understanding their market position, financial stability, and culture can provide vital insights that may influence your negotiation strategy and outcomes.

Related Posts

-

The Future of Best Wire Harness Cable Assembly in the Evolving Global Market

-

How to Choose the Best Wire Harness Wire for Future Tech Trends in 2025

-

The Future of Harness Assembly Driven by Innovation and Global Demand

-

The Ultimate Guide to Choosing the Right Harness Builder for Your Industry Needs

-

Ultimate Guide to Sourcing the Best Wire Harness Cables: Tips, Trends, and Market Insights for Global Buyers

-

7 Essential Tips for Sourcing the Best Harness Cable Assembly in 2024