How to Choose the Right Cable Assembly Wire Harness for Your Project

In the rapidly evolving landscape of electronics and automotive industries, choosing the right cable assembly wire harness is crucial for ensuring performance and reliability. According to a report by Grand View Research, the global wire harness market is projected to reach USD 61.1 billion by 2027, growing at a CAGR of 7.5%. This growth underscores the importance of selecting the appropriate cable assembly wire harness for various applications, which not only influences the efficiency of electrical systems but also affects the overall longevity and safety of devices.

With the diverse range of materials, designs, and configurations available, understanding the specific requirements of a project becomes imperative. Factors such as current capacity, environmental conditions, and space constraints must be meticulously evaluated to ensure the optimal selection of a cable assembly wire harness that meets both performance standards and industry regulations.

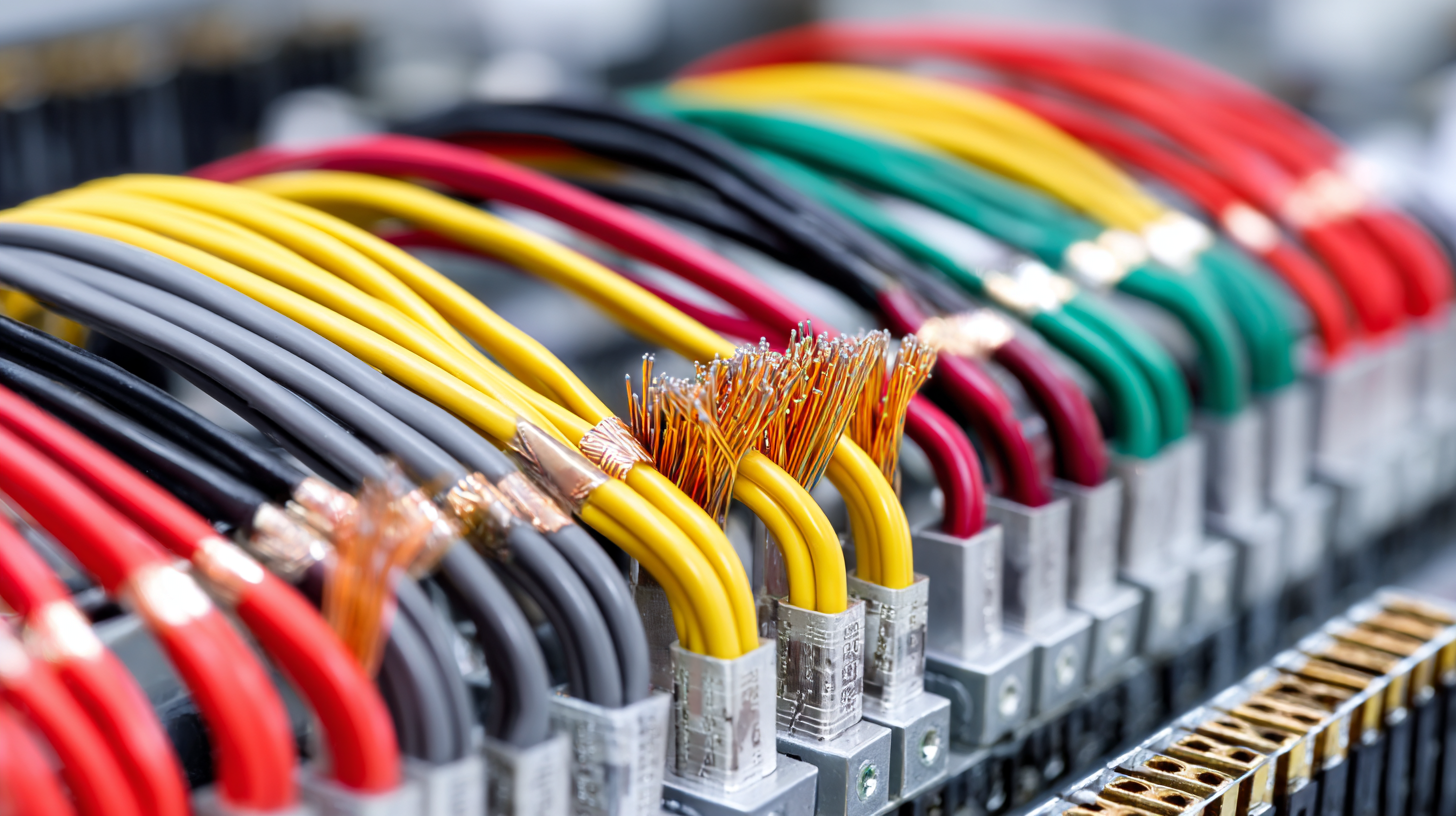

Understanding the Purpose and Functionality of Cable Assembly Wire Harnesses

Cable assembly wire harnesses play a critical role in various industries, including automotive, aerospace, and consumer electronics. These harnesses organize and protect multiple wires and cables, ensuring optimal functionality and safety in complex systems. According to a market report by Grand View Research, the global wire harness market size was valued at USD 85.2 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 6.5% from 2022 to 2030. This growth underscores the increasing reliance on sophisticated wiring solutions that enhance performance and minimize risks associated with electrical failures.

Understanding the specific purpose and functionality of cable assembly wire harnesses is essential when selecting the right solution for any project. These assemblies not only facilitate easier installation and maintenance but also reduce the chances of wire damage and short-circuiting. The right harness can optimize space, streamline production processes, and improve reliability. In fact, a report by Mordor Intelligence indicates that due to advancements in technology, such as increased demand for high-performance solutions, the market for custom wire harnesses is projected to grow significantly, illustrating the industry's shift toward more tailored, efficient wiring solutions that meet the evolving requirements of various applications.

Identifying Your Project's Specific Electrical Requirements

When embarking on a project that requires a cable assembly wire harness, the first step is to clearly identify your electrical requirements. This involves understanding the voltage, current, and environmental conditions that the harness will face. According to a report by the Market Research Future, the global wire harness market is expected to grow at a CAGR of 8.3% from 2022 to 2027, largely due to advancements in automotive and telecommunications sectors which underscore the importance of tailored electrical solutions.

Tips: Start by consulting a comprehensive electrical specification sheet that includes the parameters like wire gauge and insulation type. This will help you determine the most suitable materials that can withstand your project's specific conditions. Additionally, consider the length and routing of the harness, as these factors can significantly influence both performance and reliability.

Evaluating connectors and terminals is critical as well. Depending on the application, you'll need connectors that can handle the environmental factors such as moisture or heat exposure. Research indicates that selecting the right connector type can reduce failure rates by up to 30%, making it a crucial element in your decision-making process. Prioritize compatibility with existing systems to ensure seamless integration and optimal performance.

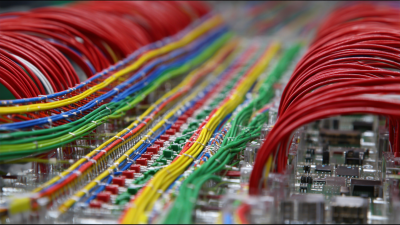

Evaluating Different Types of Cable Assembly Wire Harnesses

When evaluating different types of cable assembly wire harnesses for your project, it's essential to consider factors such as application requirements, environmental conditions, and compatibility with other components. For instance, harsh environments may necessitate the use of encapsulated or ruggedized harnesses, while standard applications may suffice with basic configurations. Understanding your specific needs can help streamline the selection process.

When evaluating different types of cable assembly wire harnesses for your project, it's essential to consider factors such as application requirements, environmental conditions, and compatibility with other components. For instance, harsh environments may necessitate the use of encapsulated or ruggedized harnesses, while standard applications may suffice with basic configurations. Understanding your specific needs can help streamline the selection process.

Tips: Always assess the materials used in the wire harness construction. Materials like PVC or Teflon can impact durability and performance. Additionally, consider the gauge of the wire—using the correct wire size guarantees optimal conductivity while preventing overheating.

Another critical factor is the assembly method. You may choose between pre-assembled units or custom designs depending on the complexity of your project. Pre-assembled harnesses offer convenience and faster deployment, while custom options provide flexibility and adaptability to unique specifications.

Tips: Before finalizing your choice, ensure thorough testing of the prototypes to validate their performance under anticipated conditions. This step not only helps in pinpointing potential failures but also allows you to make informed adjustments to your design.

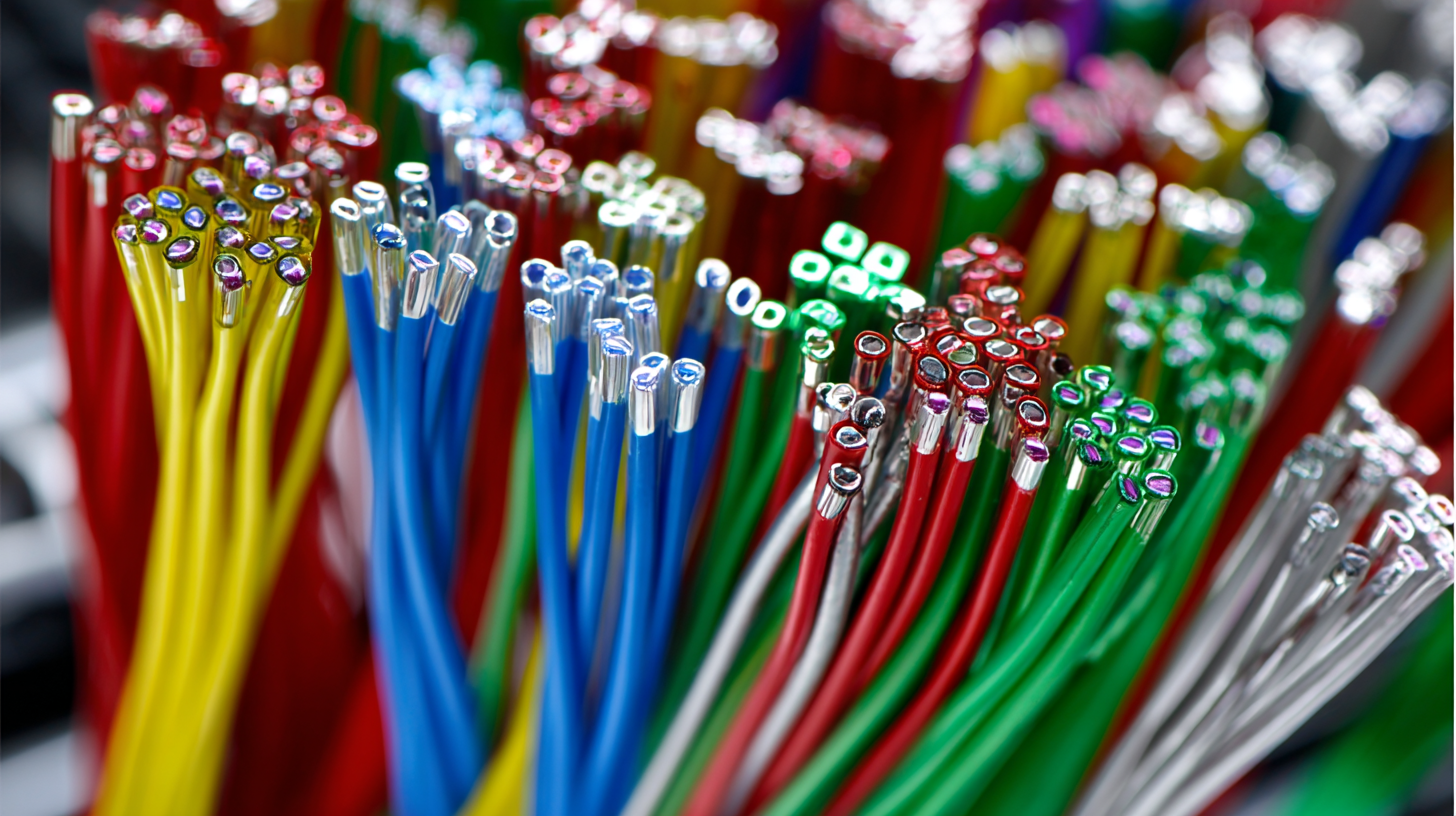

Key Factors to Consider When Selecting Materials and Components

When selecting materials and components for your cable assembly wire harness, several key factors should be considered to ensure optimal performance and durability. The growing demand for lightweight and efficient materials highlights the trend in industries like robotics and aerospace, where innovations in materials such as magnesium alloys and engineering plastics are crucial. These materials not only reduce weight but maintain structural integrity, making them ideal for wire harness applications where space and weight constraints are critical.

Additionally, sustainability and technological advancements play a significant role in material selection. The increasing focus on eco-friendly production methods can guide your choice towards more sustainable materials, ensuring compliance with global environmental standards. As markets for various materials, including carbon fiber and polypropylene, continue to expand, understanding the properties and trends associated with these materials can aid in making informed decisions that align with your project goals and performance requirements.

Tips for Ensuring Quality and Compliance in Your Wire Harness Design

When designing a wire harness, ensuring compliance with industry standards and maintaining quality is crucial for the overall success of any project. According to a report from the Wiring Harness Manufacturers Association (WHMA), nearly 30% of all product failures can be traced back to poor wire harness quality. This statistic underscores the importance of selecting high-quality materials and adhering to rigorous manufacturing processes. Utilizing wires that meet industry specifications, such as UL or CSA certifications, can significantly minimize risks associated with electrical safety and performance.

Moreover, it's essential to incorporate standardized testing during the design phase to ensure that the wire harness can withstand various environmental conditions. Reports indicate that harnesses exposed to extreme temperatures or vibrations without adequate testing may fail prematurely, leading to costly repairs or recalls. Implementing a comprehensive testing protocol not only adheres to industry regulations but also enhances the reliability of the wire harness in its intended application. Adopting these practices will bolster the integrity and functionality of your wire harness, making it a vital component of your engineering project.

Related Posts

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

The Ultimate Guide to Choosing the Best Cable Harness for Maximum Efficiency

-

7 Essential Tips for Sourcing the Best Harness Cable Assembly in 2024

-

The Future of Best Wire Harness Cable Assembly in the Evolving Global Market

-

The Future of Harness Assembly Driven by Innovation and Global Demand

-

The Definitive Ultimate Guide to Choosing the Best Harness Builder for Your Needs