How to Choose the Right Cable Assembly Wire Harness for Your Project

In today's fast-paced technological landscape, selecting the right cable assembly wire harness is crucial for the success of any electronic project. According to a report by MarketsandMarkets, the global wire harness market is projected to grow from $58.4 billion in 2021 to $79.0 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.2%. This growth underscores the increasing importance of high-quality cable assembly wire harnesses in various industries, including automotive, aerospace, and consumer electronics. With numerous options available, it is essential to consider factors such as material quality, design complexity, and regulatory compliance to ensure optimal performance and reliability. By understanding the specific needs of your project and the capabilities of different wire harnesses, you can make an informed decision that will enhance the efficiency and longevity of your electronic systems.

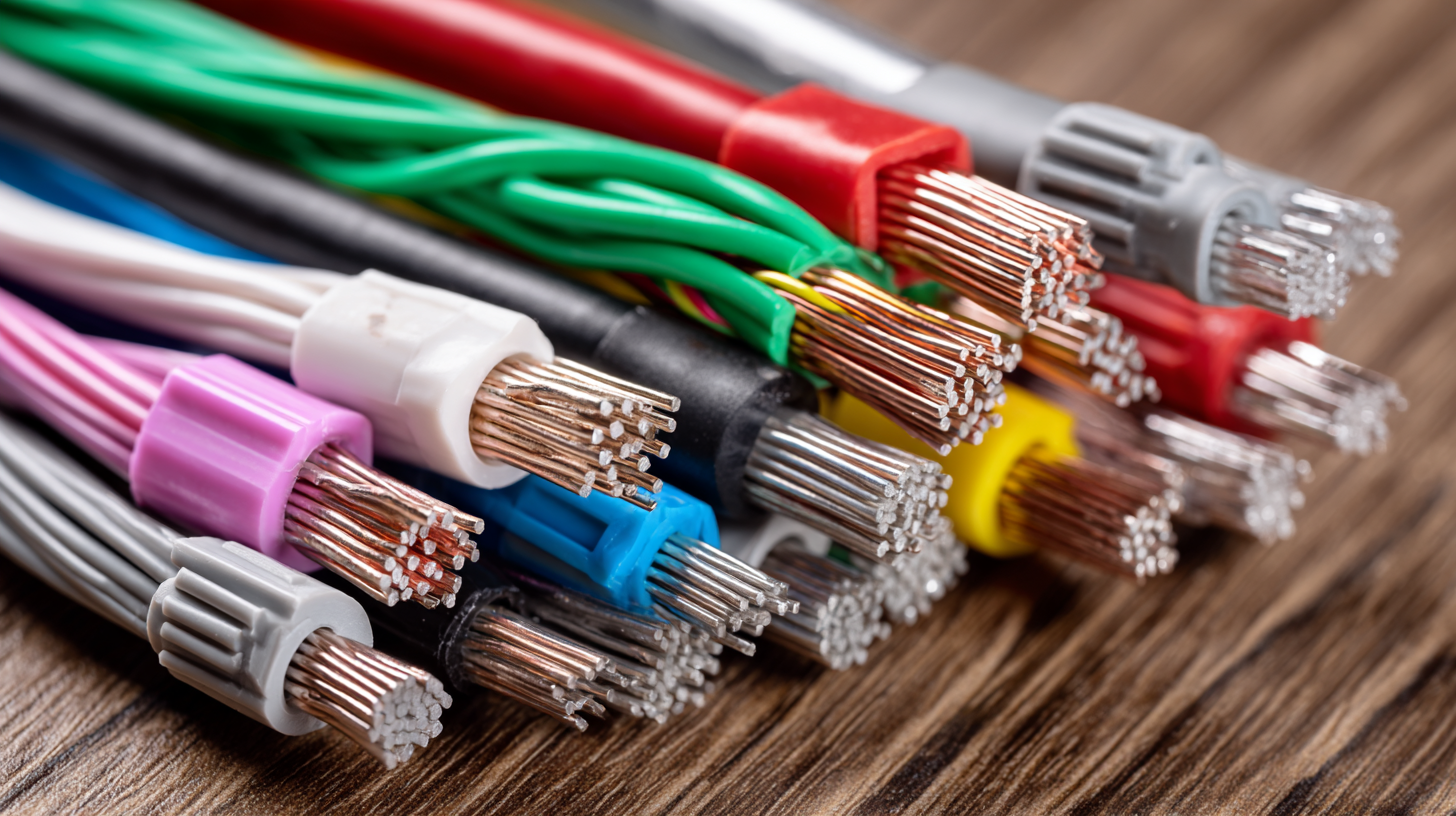

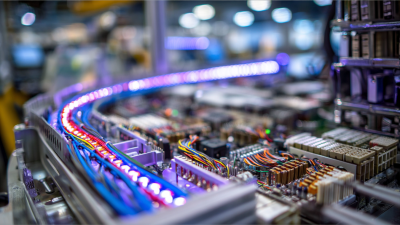

Understanding Different Types of Cable Assembly Wire Harnesses and Their Applications

When selecting a cable assembly wire harness for your project, understanding the different types and their applications is crucial. Cable assemblies can vary significantly, with options such as ribbon cable assemblies, round cable harnesses, and custom wire configurations. According to a report by MarketsandMarkets, the global market for wire harnesses is projected to reach $146.93 billion by 2025, driven by an increasing demand in automotive, aerospace, and consumer electronics industries. Each application often requires specific design considerations, such as flexibility, temperature resistance, and overall durability.

For instance, automotive wire harnesses are designed to withstand high temperatures and conform to strict safety regulations, often utilizing materials like cross-linked polyethylene (XLPE) for insulation. In contrast, consumer electronics may favor ribbon cable assemblies that offer compactness and ease of integration.

As highlighted by a study from Grand View Research, the rapid evolution of smart devices is expected to enhance the demand for highly customizable wire harness solutions, which can adapt to varying specifications. Understanding these nuances not only helps in choosing the right harness but also enhances the overall efficiency and longevity of your project's electrical systems.

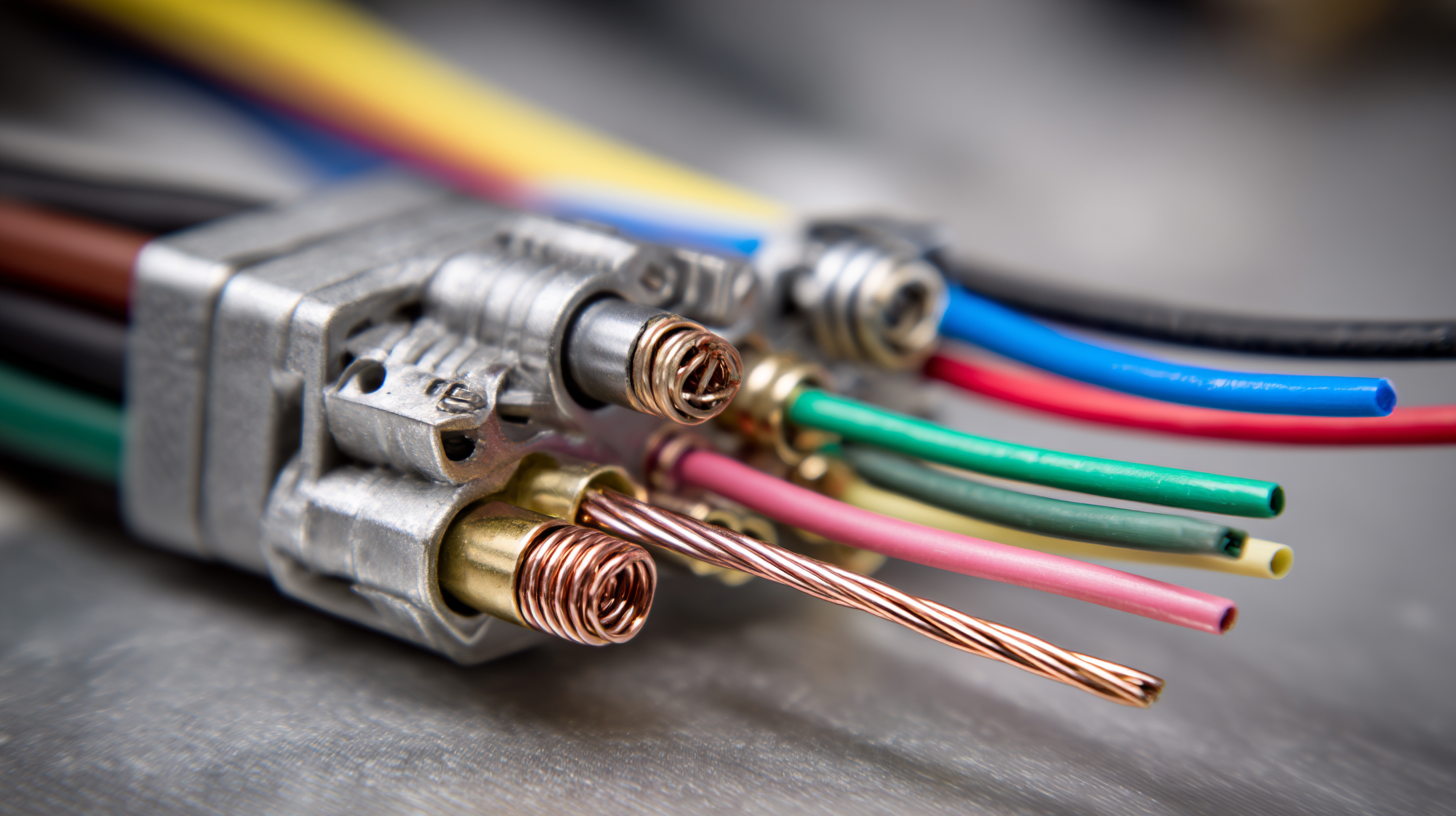

Key Factors to Consider When Selecting Cable Materials for Wire Harness Projects

When selecting cable materials for wire harness projects, several key factors must be considered to ensure optimal performance and longevity. First and foremost, the operating environment plays a crucial role in material selection. For example, cables intended for outdoor use should be resistant to UV radiation and moisture, while those deployed in extreme temperatures need to have insulating properties that can withstand such conditions. Evaluating the specific environmental challenges will help in choosing the right materials like PVC, polyurethane, or cross-linked polyethylene.

Another critical aspect to consider is the electrical requirements of the project. The gauge of the wire and the type of insulation are paramount in ensuring the harness can handle the intended voltage and current. Additionally, it's essential to assess the flexibility and mechanical strength of the materials, as wire harnesses often navigate tight spaces and experience vibrations. By prioritizing these factors, you can enhance the overall reliability and efficiency of your wire harness, ultimately contributing to the success of your project.

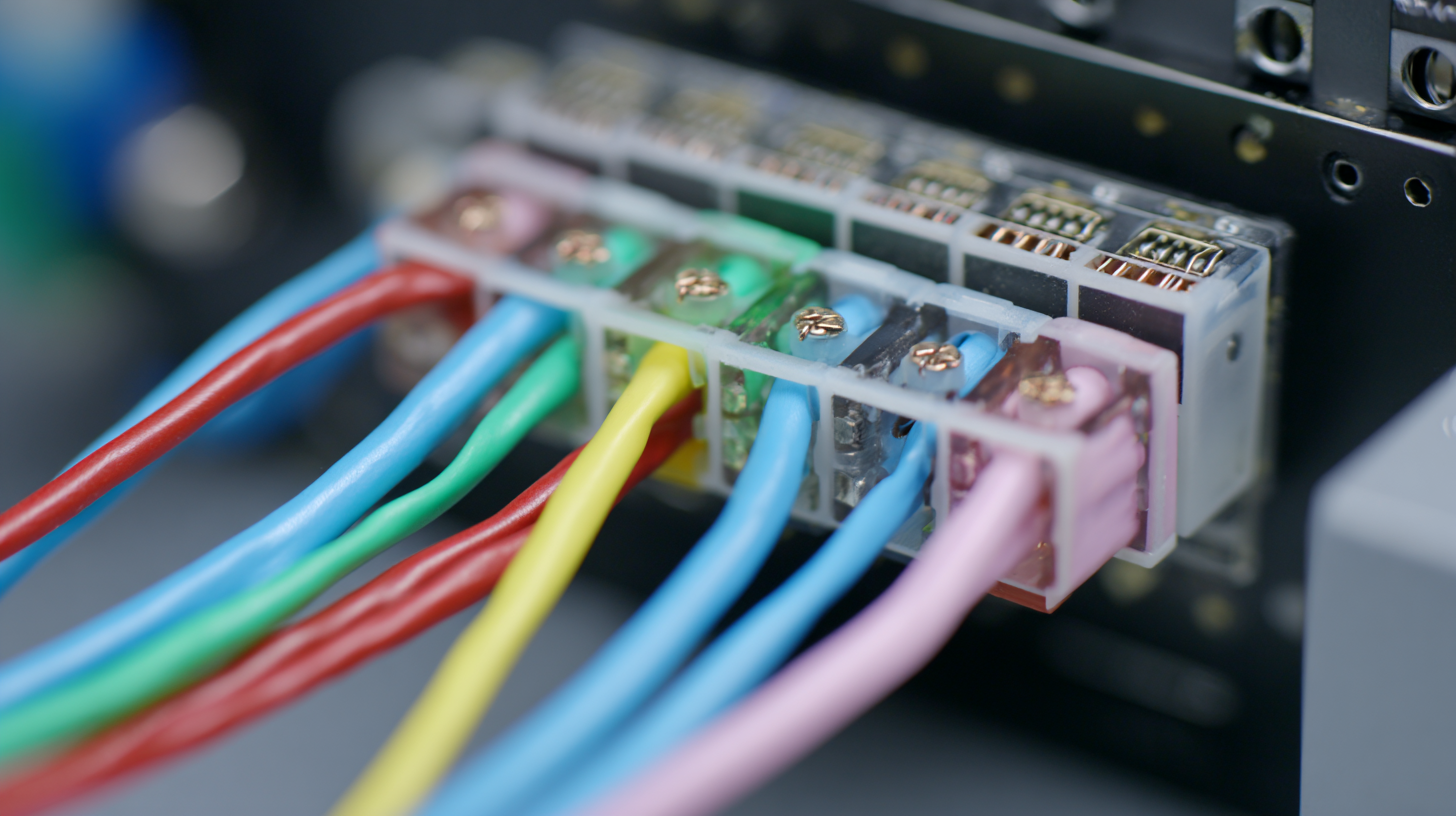

Evaluating Connector Types: A Guide to Ensuring Proper Compatibility and Performance

When selecting a cable assembly wire harness, evaluating connector types is vital for ensuring proper compatibility and performance. Each type of connector serves distinct functions and is designed for specific environments, which makes understanding their characteristics essential. For instance, if your project involves high vibrations or harsh conditions, opting for a rugged connector such as a circular or military-grade connector can enhance durability and reliability. Additionally, consider the shape and size of the connectors, as they must fit within your project's spatial constraints while ensuring ease of installation.

Another crucial factor in connector selection is the compatibility with the wire harness. Different connectors have varying pin configurations and locking mechanisms, so it’s important to ensure that they align with your existing systems. Compatibility not only impacts the function of the assembly but also enhances safety by reducing the risk of connectivity issues. Furthermore, investing in connectors that offer features such as strain relief and environmental sealing can significantly improve the performance of the wire harness in challenging conditions, thereby extending the lifespan of your project components.

Connector Types Compatibility for Cable Assembly Projects

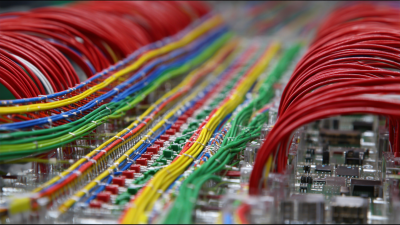

Analyzing Industry Standards and Certifications for Quality Assurance in Wire Harnesses

When selecting a cable assembly wire harness, understanding industry standards and certifications is crucial for ensuring quality assurance. Industry standards, such as ISO 9001, define the quality management systems organizations must implement to consistently provide effective products and services. According to a report by the International Organization for Standardization, organizations adhering to ISO 9001 can witness an average improvement in operational efficiency of 20%. This compliance not only enhances the reliability of wire harnesses but also minimizes risks associated with electrical failures.

Additionally, certifications like UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) are pivotal in evaluating the safety and performance of wire harnesses. Specifically, UL certification signifies that the wire harness has been tested for its ability to withstand heat, fire, and electrical hazards. Research indicates that products bearing UL certification show a significant reduction in failure rates, enhancing consumer confidence. The continuous evolution of industry standards ensures wire harness manufacturers meet stringent safety and performance requirements, ultimately leading to improved product reliability and customer satisfaction.

Through diligent consideration of these standards and certifications, project developers can select wire harnesses that align with their quality expectations and regulatory needs.

Cost vs. Quality: Making Informed Budget Decisions for Your Cable Assembly Needs

When selecting a cable assembly wire harness for your project, understanding the balance between cost and quality is crucial. Recent industry reports have shown that investing in higher-quality cables can significantly improve system performance, reducing signal loss and enhancing overall reliability. For instance, a study indicated that low-quality cables can result in up to a 30% increase in energy consumption in audio systems, leading to greater long-term costs. This highlights the importance of prioritizing quality, especially for critical applications in hi-fi setups.

While budget constraints are always a consideration, it’s essential to recognize that a lower initial expenditure on cheaper cables may lead to higher replacement rates and potential maintenance issues down the line. A survey from industry analysts revealed that consumers who opted for mid-range to high-end cables reported a 50% decrease in system-related problems. Thus, when making informed budget decisions, it’s advisable to weigh the initial cost against the potential savings from increased durability and performance efficiency, ensuring that you select a cable assembly wire harness that provides the best overall value for your specific needs.

Related Posts

-

7 Essential Tips for Sourcing the Best Harness Cable Assembly in 2024

-

The Future of Best Wire Harness Cable Assembly in the Evolving Global Market

-

What is Wire Harness Assembly and Its Impact on Electronics Industry Efficiency

-

The Future of Harness Assembly Driven by Innovation and Global Demand

-

Finding Quality Suppliers for Best Wire Harness Manufacturing Equipment

-

7 Best Practices for Effective Harness Cable Assembly Sourcing Globally