Top 10 Essential Tips for Choosing Wire Harnesses for Your Projects

In today's rapidly evolving technological landscape, the selection of wire harnesses is critical for ensuring the reliability and performance of various projects, from automotive applications to complex electronics. According to a recent report by MarketsandMarkets, the global wire harness market is projected to reach $65 billion by 2026, underscoring the growing importance and demand for high-quality wire harnesses in various industries. As these components play a crucial role in managing electrical power and signals, making informed decisions can significantly impact project success.

Industry expert Dr. Emily Carter, a leading figure in electrical engineering, states, "Choosing the right wire harness is not just about specifications; it’s about understanding the unique requirements of your project." By following essential tips for selecting wire harnesses, engineers and project managers can navigate the complexities of this increasingly intricate field. It's imperative to consider factors such as material compatibility, thermal conditions, and assembly techniques to achieve optimal performance. This guide aims to offer actionable insights and strategies that will empower professionals to make informed choices when it comes to wire harnesses, ultimately leading to enhanced project outcomes and innovation.

Understanding the Basics of Wire Harnesses and Their Applications

Wire harnesses are critical components in a wide range of applications, from automotive to aerospace and consumer electronics. A wire harness is essentially a bundle of wires or cables that transmit electrical power and signals, designed to streamline the assembly and ensure reliable operation. According to a recent report from the Markets and Markets research group, the global wire harness market was valued at approximately $107.57 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 6.5% through 2025. This growth highlights the increasing importance of wire harnesses in modern technology.

Understanding the basics of wire harnesses involves knowing the types of materials and construction techniques that can influence performance and durability. For instance, the choice of insulation material can vary significantly depending on the environment in which the harness will operate. Applications exposed to high temperatures may require specialized heat-resistant materials, while those used in wet conditions should incorporate waterproofing features. Furthermore, data from the Joint Electronics Device Engineering Council indicates that improper wire harness design can lead to electrical failures, which cause an estimated 30% of all automotive electrical issues. This underscores the necessity of selecting the right wire harness for each specific application to ensure long-term reliability and safety.

Key Factors to Consider When Selecting Wire Harness Specifications

When selecting wire harness specifications for your projects, several key factors come into play that can significantly impact performance and reliability. A recent industry report indicates that up to 30% of system failures in electrical projects can be traced back to suboptimal wire harness choices. Therefore, understanding the environment in which the harness will operate is crucial. Thermal conditions, exposure to chemicals, and mechanical stress should be evaluated thoroughly to ensure the selected materials and configurations can withstand these challenges. For example, high-temperature environments may necessitate the use of specialized insulation materials that maintain performance over a prolonged period without degrading.

Another critical aspect to consider is the specific electrical requirements of your application. Wire gauge, conductor material, and insulation type all influence not only the conductivity but also the overall durability and safety of the harness. Research shows that using the appropriate gauge can prevent overheating and reduce voltage drop, which is essential for maintaining the efficiency of the system. Furthermore, compatibility with connectors and adherence to industry standards, such as IPC/WHMA-A-620, should guide your selection process to ensure both compliance and long-term reliability. By carefully assessing these factors, you can optimize your design and mitigate the risks associated with wire harness failures.

Top 10 Essential Tips for Choosing Wire Harnesses for Your Projects

| Tip Number | Tip Description | Key Factors |

|---|---|---|

| 1 | Understand Your Project Requirements | Voltage, Current, Environment |

| 2 | Choose the Right Wire Gauge | Amperage, Length |

| 3 | Select Appropriate Insulation Material | Temperature Rating, Chemical Resistance |

| 4 | Consider Connector Types | Durability, Ease of Use |

| 5 | Plan for Environmental Factors | Moisture, Temperature, Vibration |

| 6 | Evaluate Assembly Techniques | Soldering vs Crimping |

| 7 | Consider Heat Shrink Tubing | Protection, Insulation |

| 8 | Test Your Harness Before Full Production | Functionality, Reliability |

| 9 | Review Compliance with Standards | Industry Safety, Environmental Regulations |

| 10 | Consult with Experts if Needed | Professional Advice, Experience |

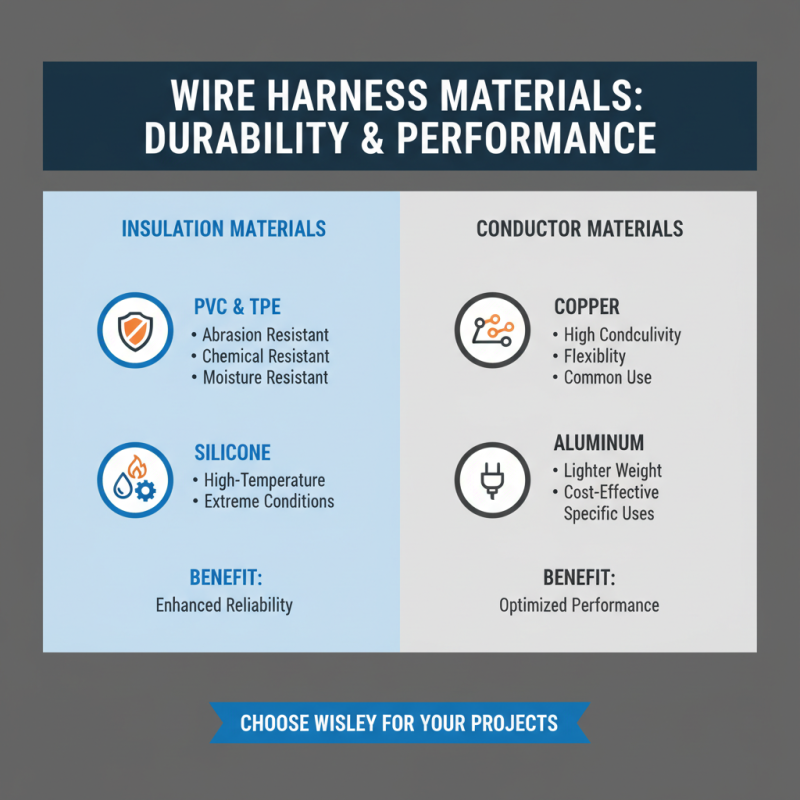

Material Choices: Optimizing Durability and Performance in Wire Harnesses

When it comes to selecting wire harnesses for your projects, choosing the right materials is crucial for optimizing both durability and performance. The type of insulation and conductor materials used can significantly impact the overall reliability of the harness. For example, materials like polyvinyl chloride (PVC) and thermoplastic elastomers (TPE) are popular for their excellent resistance to abrasion, chemicals, and moisture, making them suitable for a range of environments. Additionally, high-temperature materials such as silicone are essential for applications that involve extreme conditions, ensuring that the wire harness operates effectively without compromising safety.

Furthermore, the choice of conductor material also plays a vital role in the performance of wire harnesses. Copper is the most commonly used conductor due to its excellent electrical conductivity and flexibility. However, in specific applications where weight and corrosion resistance are critical, alternatives like aluminum or copper-clad aluminum may be considered. By carefully evaluating the requirements of your project, including temperature ranges, potential exposure to chemicals, and mechanical stress factors, you can select wire harness materials that not only meet your performance needs but also enhance the longevity of your electrical systems.

Evaluating Customization Options for Your Wire Harness Needs

When it comes to selecting wire harnesses for your projects, evaluating customization options is crucial. Custom wire harnesses are designed to meet specific requirements, ensuring optimal performance and reliability. Begin by assessing the particular functionalities you need. For instance, consider the types of connectors, the gauge of wires, and the required insulation. Each project has unique demands; therefore, understanding these requirements can help guide your customization process effectively. Another key aspect of customization is the adaptability to different environments and applications. Depending on the nature of your project, you may need wire harnesses that can withstand various temperatures, moisture levels, or exposure to chemicals. Look for manufacturers who offer flexibility in design to tailor the wire harness to suit these environmental factors while maintaining safety standards. Collaboration with engineers or consultants during the design phase can further enhance the quality and functionality of your wire harness, resulting in a product that truly fits your project's needs.

Ensuring Safety and Compliance in Wire Harness Design and Use

When designing and utilizing wire harnesses, ensuring safety and compliance is paramount. One crucial aspect is understanding the specific requirements and standards related to your industry. Different sectors may have unique regulations that govern wire harnesses, including electrical, automotive, and aerospace industries. Familiarizing yourself with these standards not only helps in meeting necessary compliance but also enhances the overall safety of your projects.

When selecting wire harnesses, always assess the materials used. The quality of materials can significantly affect both performance and safety. Using high-quality insulation and connectors helps to prevent short circuits and reduce the risk of overheating. Additionally, ensure that the wire gauge is appropriate for the electrical load, as using inadequate wire can lead to dangerous failures.

Moreover, consider the environment in which the wire harness will operate. Factors like temperature, moisture, and potential exposure to chemicals can influence the choice of materials and design features. Implementing protective measures, such as heat-shrink tubing and proper sealing methods, can enhance durability and compliance with safety standards. By prioritizing these tips in your wire harness selection process, you can effectively ensure a safer and more compliant project outcome.

Top 10 Essential Tips for Choosing Wire Harnesses

Related Posts

-

Top 10 Wire Harness Manufacturing Techniques for Efficient Production

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

The Future of Best Wire Harness Cable Assembly in the Evolving Global Market

-

How to Choose the Best Wire Harness Wire for Future Tech Trends in 2025

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production

-

7 Best Wire Harness Cable Innovations Revolutionizing Industry Standards