The Future of Harness Assembly Driven by Innovation and Global Demand

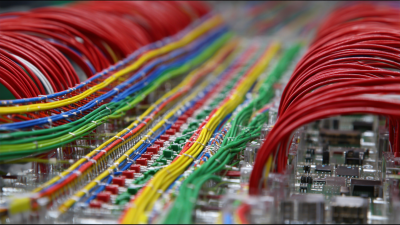

As global demand for advanced manufacturing solutions continues to escalate, the harness assembly sector is undergoing a transformative evolution driven by innovation. According to a recent report by Market Research Future, the global harness assembly market is projected to reach $XX billion by 2025, growing at a CAGR of XX%. This growth is propelled by the increasing need for connectivity in automotive, aerospace, and industrial applications, with harness assemblies playing a pivotal role in ensuring reliable electrical connections. Companies are investing in cutting-edge technologies such as automation and smart manufacturing to enhance efficiency and precision in harness assembly processes. As we delve into the future of harness assembly, we will explore how businesses can adapt to this rapidly changing landscape, harnessing the power of innovation to meet the surging global demand effectively.

The Impact of Digital Transformation on Harness Assembly Efficiency

Digital transformation is reshaping the landscape of harness assembly, elevating efficiency and responsiveness in an increasingly competitive market. According to recent studies, 70% of manufacturers are planning to invest significantly in digital technologies within the next few years, recognizing that these innovations are not merely objectives but essential enablers for operational excellence. By leveraging advanced technologies such as AI and IoT, companies can streamline their processes, enhance quality control, and reduce lead times, ultimately driving customer satisfaction and loyalty.

In the realm of harness assembly specifically, the integration of digital tools allows for greater customization and faster production cycles. Reports indicate that organizations utilizing AI-driven analytics can improve their decision-making speed by up to 50%, adapting swiftly to shifting global demands. Moreover, as businesses aim for sustainability amidst the dual challenges of green and digital transitions, digital transformation becomes crucial in developing more resilient supply chains. By harnessing data effectively, manufacturers can identify inefficiencies and implement eco-friendly practices, thus not only meeting regulatory requirements but also resonating with increasingly conscious consumers.

Emerging Technologies Revolutionizing Harness Design and Production

The future of harness assembly is being significantly shaped by emerging technologies that revolutionize the design and production processes. Innovations such as automation through cartesian robotics and additive manufacturing are at the forefront, streamlining operations that were once manual and time-consuming. This shift not only enhances manufacturing efficiency but also allows for greater precision and customization in harness assembly, catering to the growing global demand for advanced solutions.

Furthermore, the integration of artificial intelligence in manufacturing is paving the way for smarter production techniques. AI applications help in anticipating market needs and optimizing resource allocation, reducing waste and boosting productivity. Such advancements reflect a broader trend across various industries, including healthcare and energy, where emerging technologies continue to redefine conventional methodologies. As we embrace these innovations, the potential for a more agile, efficient, and responsive harness assembly process becomes increasingly clear, positioning the industry for a sustainable future.

Market Trends: The Surge in Global Demand for Harness Assemblies

The global demand for harness assemblies is witnessing remarkable growth, driven by advancements in various sectors such as automotive, aerospace, and renewable energy. According to a recent report by Market Research Future, the harness assembly market is projected to reach USD 147 billion by 2027, expanding at a compound annual growth rate (CAGR) of 7.5% from 2020 to 2027. This surge is largely attributed to the increasing need for efficient cable management solutions and the proliferation of electric vehicles, which require sophisticated wiring harness systems to ensure optimal functionality.

Moreover, the rise of smart technologies and automation has further escalated the demand for harness assemblies in industrial applications. A report from Grand View Research highlights that the automotive segment is expected to dominate the market, accounting for over 40% of the total market share by 2025. Factors such as stringent regulations on vehicle emissions and the shift towards electrification are propelling manufacturers to innovate and produce high-performance harness assemblies that meet the evolving needs of the industry. This innovation not only addresses global demand but also promotes sustainability within the supply chain by minimizing waste and optimizing resource utilization.

Data-Driven Innovation: Improving Quality Control in Harness Manufacturing

The evolving landscape of harness manufacturing is increasingly shaped by data-driven innovation, particularly in the realm of quality control. As global demand for high-quality harness assemblies continues to rise, manufacturers are leveraging advanced data analytics to ensure that every component meets stringent industry standards. By utilizing real-time data monitoring and predictive analytics, companies can identify potential defects in the production process before they escalate into larger issues, thus maintaining a consistently high level of quality.

Additionally, the integration of Internet of Things (IoT) technology has revolutionized the way manufacturers approach quality control. Sensors embedded in machinery and materials collect vast amounts of data, providing insights into the manufacturing environment. This not only facilitates immediate rectifications but also enables manufacturers to track performance trends over time. The proactive approach allows for continuous improvement, ensuring that products not only meet but exceed customer expectations. As innovation continues to drive the industry forward, data-driven strategies will play a crucial role in achieving operational excellence and meeting the demands of a competitive market.

The Future of Harness Assembly Driven by Innovation and Global Demand

| Dimension | 2022 | 2023 | 2024 (Projected) |

|---|---|---|---|

| Global Demand (Units) | 1,500,000 | 1,800,000 | 2,200,000 |

| Quality Control Rate (%) | 85 | 90 | 95 |

| Manufacturing Efficiency (Units/Hour) | 50 | 60 | 70 |

| Average Defect Rate (%) | 15 | 10 | 5 |

| Investment in Automation ($ Millions) | 200 | 250 | 300 |

Sustainability Practices in Harness Assembly: Meeting Global Standards

Sustainability has become a guiding principle in harness assembly, driven not only by global demand but also by an urgent need for cohesive practices that adhere to stringent environmental standards. As industries evolve, the integration of innovative production technologies is essential to meet these sustainability benchmarks. Drawing inspiration from emerging trends in sustainable materials, the harness assembly sector is now at a crossroads where it must adopt advanced methodologies that prioritize eco-friendliness and efficiency. This strategic shift not only aids in reducing carbon footprints but also enhances the performance reliability of harness assemblies.

Incorporating concepts from Industry 4.0 enables the utilization of intelligent manufacturing processes and data-driven insights, further promoting sustainability in harness assembly. By leveraging artificial intelligence and the Industrial Internet of Things (IoT), manufacturers can optimize resource use and waste management practices. This holistic approach not only improves productivity but also aligns with global efforts to foster sustainable development. As regions come together to enhance geospatial capabilities and finance initiatives, the harness assembly industry must remain adaptive, embracing interdisciplinary collaboration to innovate and create robust solutions that meet the demands of a sustainable future.

Related Posts

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

Ultimate Guide to Sourcing the Best Wire Harness Cables: Tips, Trends, and Market Insights for Global Buyers

-

Global Sourcing of Premium Electronic Wire Harnesses: China's Quality Leads the Way

-

How to Choose the Best Wire Harness Wire for Future Tech Trends in 2025

-

Finding Quality Suppliers for Best Wire Harness Manufacturing Equipment

-

The Future of Best Wire Harness Cable Assembly in the Evolving Global Market