Harness Manufacturing Innovations at China Import and Export Fair in 2025

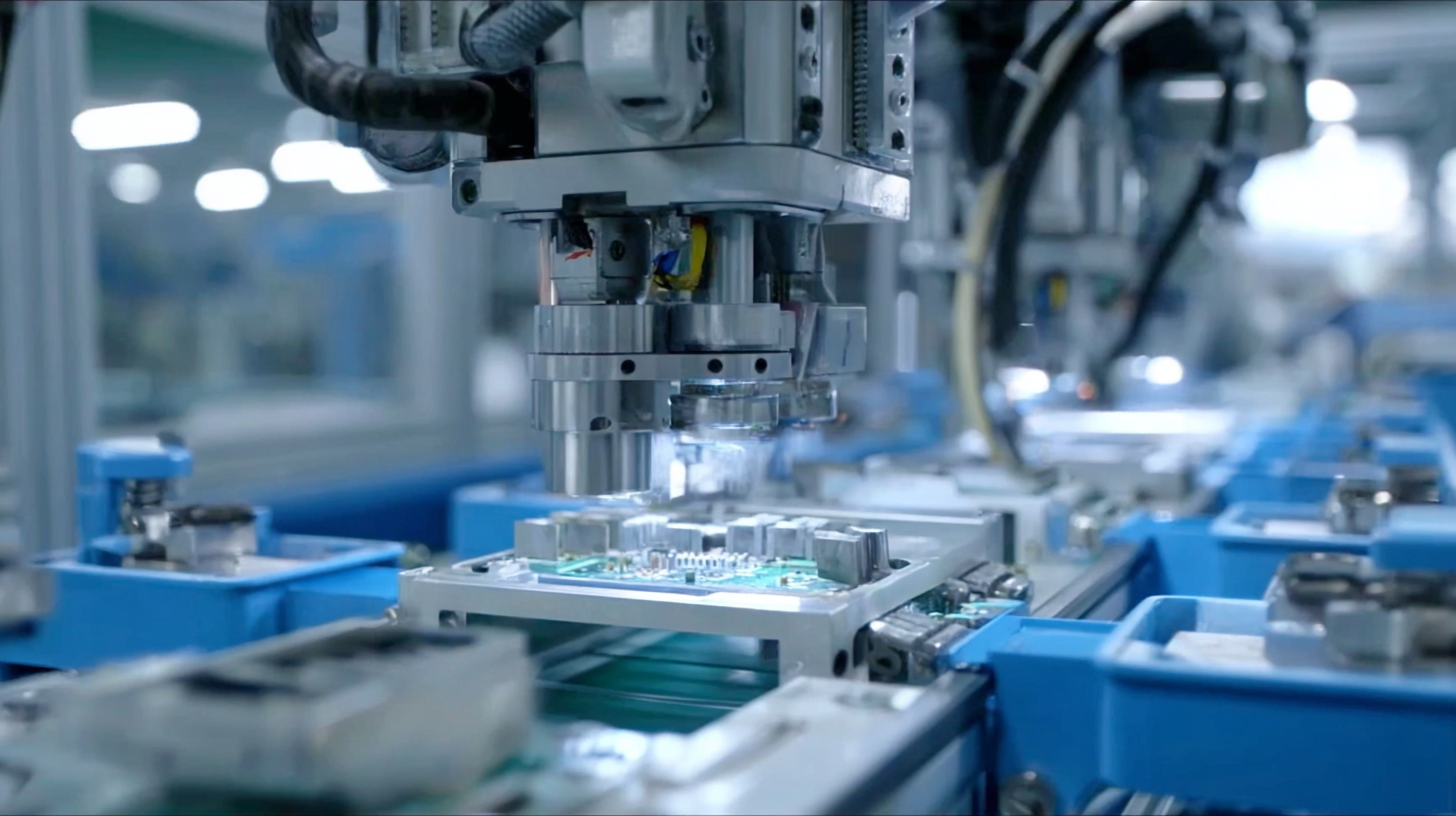

The 138th China Import and Export Fair in 2025 represents a pivotal moment for the global manufacturing landscape, particularly in the realm of harness manufacturing. As industry reports from the International Federation of Robotics indicate, the adoption of advanced automation technologies has surged by over 30% annually in China, streamlining production processes and enhancing efficiency. Furthermore, the increasing demand for high-quality wire harnesses in sectors such as automotive and electronics is projected to grow by 15% through 2027, driven by trends toward electrification and smart technologies.

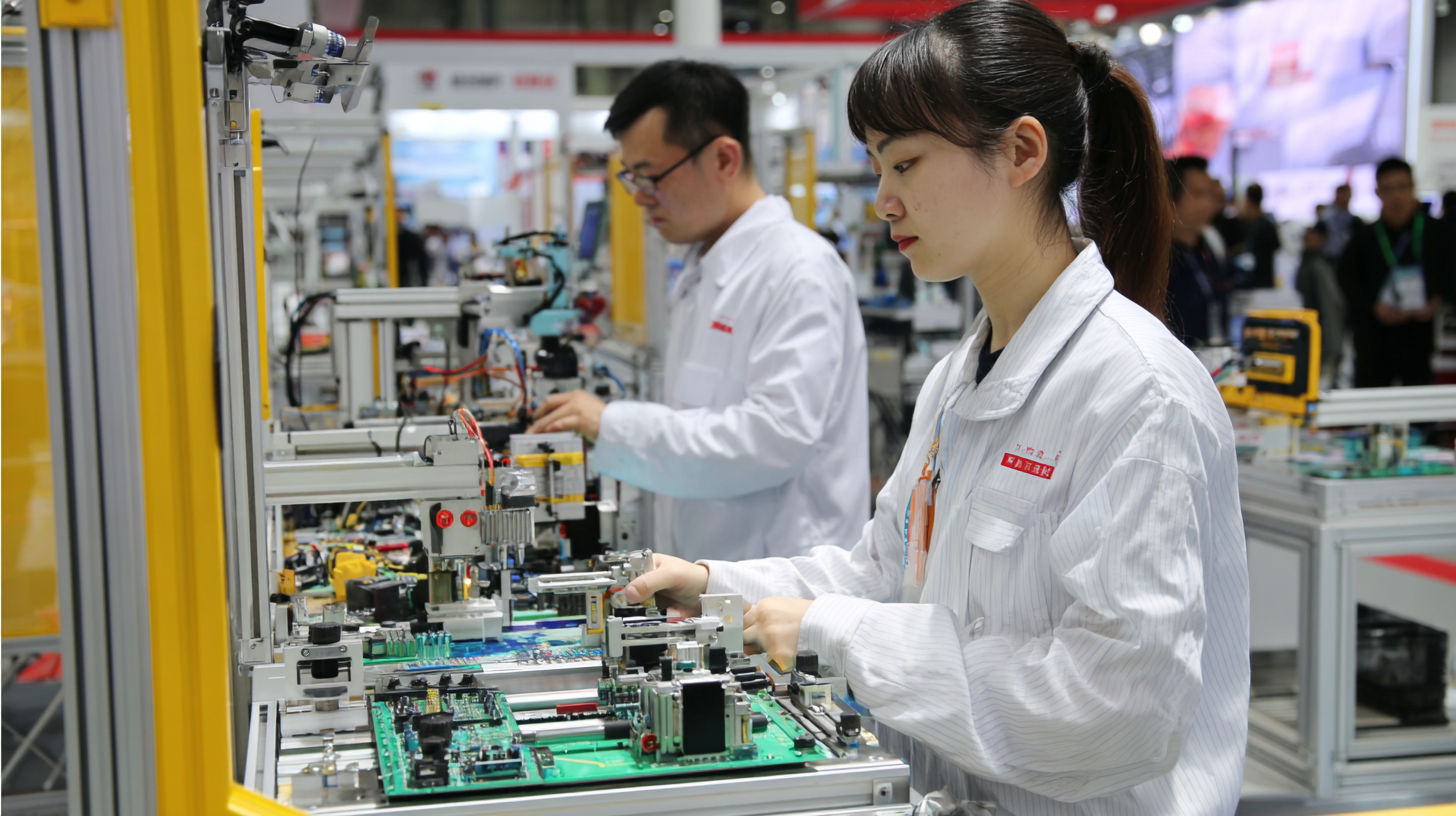

The fair will serve as a vital platform for showcasing innovations in harness manufacturing, fostering partnerships, and exploring cutting-edge solutions that meet the evolving market needs. As manufacturers gather to share insights and advancements, the fair promises to illuminate the future trajectory of harness manufacturing within the dynamic landscape of international trade.

Exploring the Latest Manufacturing Innovations Showcased at the Fair

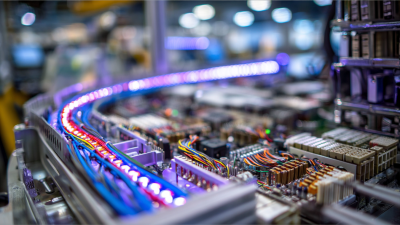

The China Import and Export Fair, also known as the Canton Fair, is set to showcase cutting-edge manufacturing innovations in 2025, focusing on smart manufacturing and sustainable production practices. As global manufacturing sectors increasingly pivot towards Industry 4.0, this event will highlight technologies such as artificial intelligence, automation, and data analytics. According to a report by McKinsey, 70% of manufacturers have accelerated their digital initiatives in response to recent disruptions, showcasing the critical need for innovation in this sector.

Key Trends in Sustainable Manufacturing Practices at the Canton Fair

The Canton Fair in 2025 is set to showcase pivotal advancements in sustainable manufacturing practices, reflecting a global shift towards greener operations in the metal forging industry. As technology progresses, the integration of automation and smart manufacturing techniques is becoming imperative. This evolution not only enhances efficiency but also aligns with sustainability goals. The demand for innovative, eco-friendly products is increasingly shaping market dynamics, prompting companies to adapt and invest in advanced manufacturing processes.

Amidst changing market demands, experts emphasize the importance of flexible strategic planning to capture new global opportunities. The introduction of carbon border adjustment mechanisms in the EU highlights the urgent need for industries to comply with stringent environmental regulations. In this context, Chinese companies are compelled to enhance their sustainability reports and performance, responding proactively to global market trends. By investing in green technologies and adopting sustainable practices, manufacturers will not only meet compliance standards but also position themselves competitively in an evolving marketplace.

Networking Opportunities for Manufacturers and Suppliers at the Expo

The China Import and Export Fair in 2025 is poised to be a pivotal platform for manufacturers and suppliers aiming to leverage new manufacturing innovations. This event is not only a showcase of cutting-edge technologies but also a golden opportunity for networking. According to a recent industry report by the China Council for the Promotion of International Trade, 75% of exhibitors cite networking as a primary benefit of attending the fair, highlighting its significance in the manufacturing sector.

Manufacturers can connect with suppliers, distributors, and potential clients, fostering relationships that can lead to lucrative partnerships. The fair is expected to attract over 200,000 visitors, creating a vibrant environment for exchanging ideas and forging collaborations. Occupational trends indicate that companies that prioritize networking improve their market competitiveness by 30%, making the fair an essential stop for manufacturers looking for growth.

**Tips for Maximizing Networking Opportunities:**

- **Prepare Your Elevator Pitch**: A concise introduction about your company and its unique offerings can leave a lasting impression.

- **Utilize Social Media**: Engage with other attendees on platforms like LinkedIn before the event to set up meetings and make connections.

- **Follow Up**: After the fair, send personalized messages to new contacts to keep the conversation going and build on the relationship.

Manufacturing Innovations Metrics at China Import and Export Fair 2025

This chart represents the number of manufacturing innovations presented at the China Import and Export Fair in 2025, highlighting key areas such as 3D printing, automation, and sustainable materials.

Impact of Advanced Technologies on the Future of Manufacturing in China

The China Import and Export Fair in 2025 is set to showcase cutting-edge advancements in manufacturing technologies that are reshaping the landscape of production in the country. As businesses adapt to these innovations, the emphasis will be on integrating advanced technologies such as artificial intelligence, automation, and smart manufacturing systems. These technologies not only enhance efficiency but also improve product quality and reduce costs, positioning Chinese manufacturers to compete more effectively on a global scale.

Tips: Embrace digital transformation by investing in training for your workforce. Knowledgeable employees can leverage technology to optimize processes and drive innovation. Consider building partnerships with tech firms to stay ahead of the curve and ensure access to the latest advancements.

As we look to the future, the role of sustainability in manufacturing cannot be overlooked. Advanced technologies enable not only better resource management but also the implementation of greener production practices. Companies that prioritize sustainability will likely see increased consumer trust and loyalty, enhancing their brand reputation.

Tips: Start small by evaluating your current processes for sustainability opportunities. Even minor adjustments can lead to significant improvements in environmental impact and operational efficiency. Engage with consumers to understand their sustainability expectations and incorporate feedback into your strategies.

Case Studies of Successful Innovations Displayed at the 138th Canton Fair

The 138th Canton Fair showcased a plethora of innovative manufacturing solutions, setting a benchmark for future industry standards. One standout case was an environmentally friendly packaging solution presented by a leading Chinese firm, which utilized bioplastics to reduce waste. This innovation not only addressed global sustainability concerns but also captured interest from international buyers looking to align with eco-conscious practices. Such successful displays at the fair highlight the importance of innovation in enhancing competitiveness in the global market.

Tip: When attending expos like the Canton Fair, pay close attention to companies that focus on sustainability in their product designs, as these innovations can significantly impact consumer preferences and brand loyalty.

Another remarkable case involved smart manufacturing technologies, where a Chinese manufacturer demonstrated their new AI-driven quality control system. This technology drastically improved defect detection rates and reduced manufacturing costs, setting a precedent for efficiency in production lines. The integration of advanced technologies like AI and IoT in manufacturing processes not only showcases innovation but also reflects a larger trend towards digital transformation in the industry.

Tip: Engage with exhibitors showcasing cutting-edge technologies and inquire about their systems; understanding their benefits could provide valuable insights for your own operations.

Related Posts

-

The Future of Harness Assembly Driven by Innovation and Global Demand

-

Comparing Different Approaches to Wire Harness Manufacturing Techniques

-

What is Wire Harness Assembly and Its Impact on Electronics Industry Efficiency

-

7 Essential Tips for Sourcing the Best Harness Cable Assembly in 2024

-

Finding Quality Suppliers for Best Wire Harness Manufacturing Equipment

-

5 Essential Tips for Choosing the Best Wire Harness Manufacturing Equipment