What is the Importance of Cable Wire Harness Assembly in Modern Electronics

In today's rapidly evolving electronics landscape, the importance of cable wire harness assembly cannot be overstated. As industries continue to push for smaller, more efficient designs, the demand for reliable and compact wiring solutions has surged. According to a report by Grand View Research, the global wiring harness market is expected to reach approximately $70 billion by 2025, driven largely by advances in automotive and consumer electronics. This underscores the critical role that cable wire harness assemblies play in enabling the functionality and performance of various devices, from automobiles to household appliances.

These assemblies not only streamline production processes but also enhance connectivity and durability, ultimately contributing to the overall reliability of electronic systems. As technology advances and IoT integration expands, the significance of efficient and quality cable wire harness assembly will only continue to grow, making it an essential focus for manufacturers aiming to stay competitive in the market.

Understanding Cable Wire Harness Assembly: A Key Component in Electronics

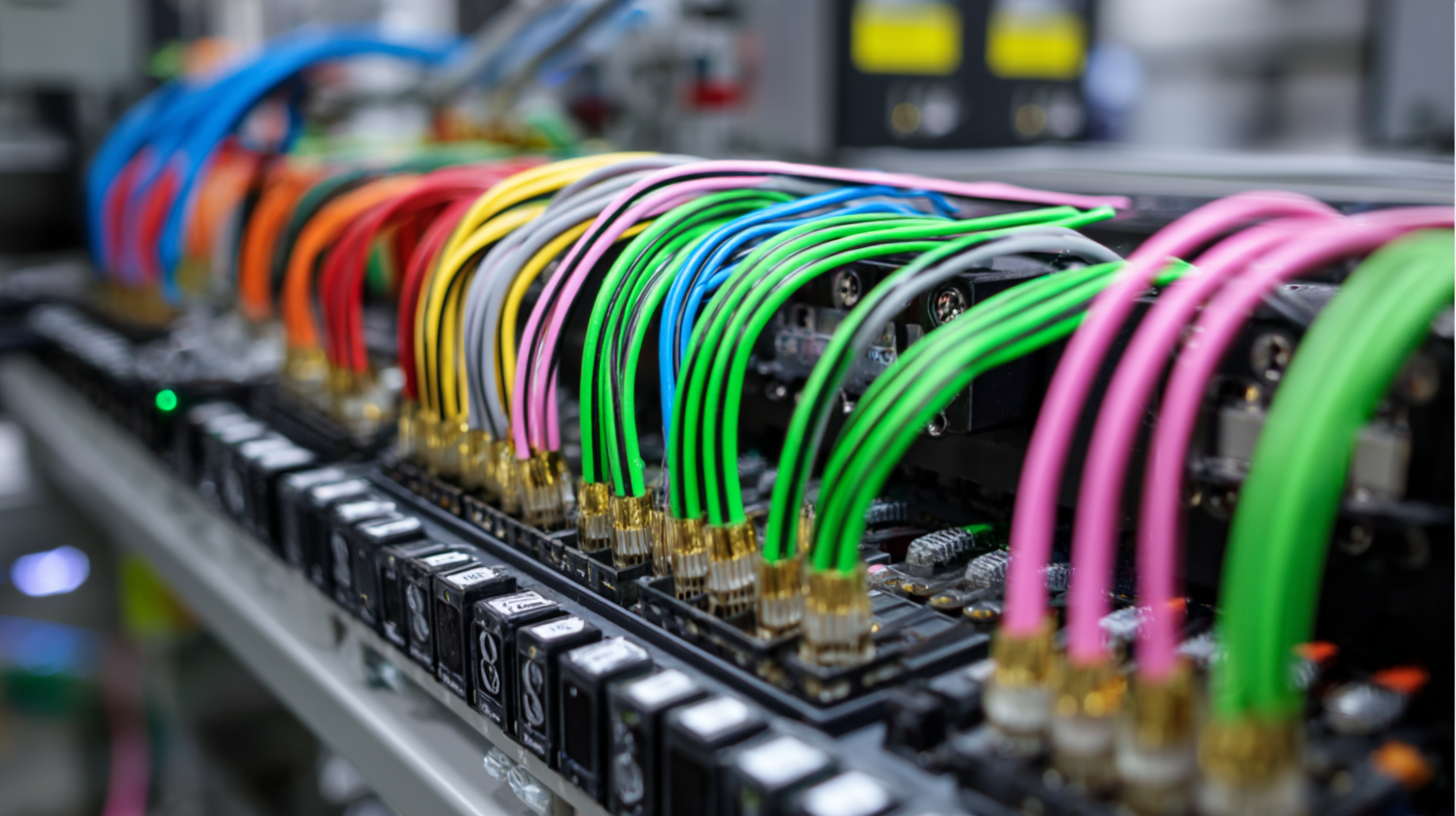

Cable wire harness assembly plays a crucial role in modern electronics by providing a structured way to organize and connect multiple wires and cables within a system. This assembly not only enhances the efficiency of the electronic device but also ensures reliability and safety. By bundling wires together, businesses can minimize the risk of wear and tear, thereby prolonging the lifespan of the components involved.

Moreover, cable wire harness assemblies streamline the manufacturing process. By pre-assembling the cables, manufacturers can significantly reduce installation time and complexity, allowing for faster production cycles. This efficiency is especially vital in industries where time-to-market is a significant competitive factor. Furthermore, properly designed harness assemblies improve signal integrity and reduce the potential for electrical interference, ultimately resulting in better performance of electronic devices.

Advantages of Using Cable Wire Harness Assemblies in Modern Devices

Cable wire harness assemblies play a pivotal role in modern electronics, providing a streamlined solution for connecting various components efficiently. One of the key advantages of using these assemblies is their ability to significantly reduce assembly time and costs. Reports indicate that companies can save up to 30% in labor costs by utilizing wire harnesses, as they simplify the process of integrating multiple wires into a single, organized unit. Furthermore, cable harnesses help in minimizing the risk of errors during installation, resulting in a more reliable and robust electronic device.

In addition to labor savings, cable wire harness assemblies also enhance the durability and performance of devices. These assemblies offer superior protection against environmental factors such as vibration, heat, and moisture. According to a study by the Institute of Electrical and Electronics Engineers (IEEE), devices equipped with advanced wire harness systems demonstrate a 20% increase in lifespan compared to those using traditional wiring methods.

Tips: When designing or selecting a cable wire harness assembly, consider custom solutions tailored to specific applications. Employing high-quality materials and adhering to industry standards can further improve performance and reliability. Always consult with a professional to ensure compliance with relevant regulations and best practices in the manufacturing process.

Common Applications of Cable Wire Harnesses in Various Industries

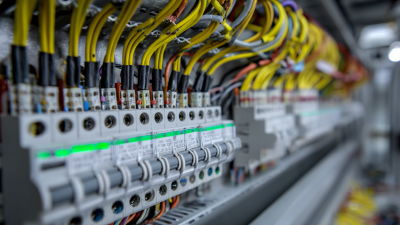

Cable wire harness assemblies play a critical role in modern electronics, serving as a vital component in a wide range of industries. One common application is in the automotive sector, where wire harnesses connect various electronic components like sensors, lights, and infotainment systems. These assemblies are designed to meet the rigorous demands of automotive environments, providing durability and reliability for vehicles. Additionally, in consumer electronics, cable harnesses are essential for interconnecting circuit boards, displays, and power supplies in devices such as phones, laptops, and televisions.

Cable wire harness assemblies play a critical role in modern electronics, serving as a vital component in a wide range of industries. One common application is in the automotive sector, where wire harnesses connect various electronic components like sensors, lights, and infotainment systems. These assemblies are designed to meet the rigorous demands of automotive environments, providing durability and reliability for vehicles. Additionally, in consumer electronics, cable harnesses are essential for interconnecting circuit boards, displays, and power supplies in devices such as phones, laptops, and televisions.

In the aerospace and defense industries, the importance of cable wire harnesses increases significantly due to stringent safety and performance requirements. These harnesses are engineered to withstand extreme temperatures and vibrations, ensuring that communication systems and navigation equipment function flawlessly. Similarly, in the medical field, wire harnesses are critical in connecting devices that monitor patient health, allowing for precise diagnoses and treatments.

Tips: When choosing a cable wire harness for your application, consider factors such as abrasion resistance, environmental conditions, and the specific connector types needed. Customizing your cable harness can also lead to enhanced performance, so always consult with manufacturers for tailored solutions. Additionally, regular testing and inspection of your wire harness can prevent potential failures, ensuring your systems operate smoothly.

Tips for Selecting the Right Cable Wire Harness for Your Project

When selecting the right cable wire harness for your project, the first step is to assess the specific requirements of your application. Consider factors such as the environment in which the harness will operate, including temperature ranges, exposure to moisture, and potential chemical exposure. A thorough understanding of these conditions helps you choose materials that are durable and reliable, ensuring the harness can withstand its operating environment.

Next, think about the electrical specifications needed for your project. Pay attention to factors such as current load, voltage levels, and the possibility of electromagnetic interference. Proper insulation and shielding can significantly affect performance, so it’s crucial to select harnesses that meet or exceed safety standards for electrical performance. Finally, consider customization options, as tailored designs can enhance functionality and streamline your assembly process, ultimately leading to a more efficient and effective electronic system.

What is the Importance of Cable Wire Harness Assembly in Modern Electronics - Tips for Selecting the Right Cable Wire Harness for Your Project

| Parameter | Description | Considerations |

|---|---|---|

| Wire Type | Copper, Aluminum, or Specialty Alloy | Conductivity, Flexibility, and Cost |

| Insulation Material | PVC, Teflon, Silicone, etc. | Temperature Resistance, Chemical Resistance |

| Wire Gauge | AWG (American Wire Gauge) measurement | Current Rating, Voltage Drop |

| Connector Type | Molex, JST, DIN, etc. | Compatibility, Ease of Assembly |

| Assembly Method | Hand assembly, automated assembly | Cost, Precision, Volume |

| Application | Automotive, Aerospace, Consumer Electronics, etc. | Environment, Regulatory Compliance |

Future Trends in Cable Wire Harness Technology and Their Impact on Electronics

As technology continues to advance, the future of cable wire harness assembly in modern electronics is poised for significant transformation. Innovations such as the adoption of artificial intelligence and automation in manufacturing processes promise to streamline the production of wire harnesses, enhancing their precision and reducing lead times. This trend is likely to lead to more compact and efficient designs, enabling electronics to become smaller and more powerful without compromising on performance or reliability.

Moreover, the growing emphasis on sustainability is likely to influence the development of cable wire harness technologies. Manufacturers are increasingly focusing on reducing waste and utilizing eco-friendly materials in their products. This shift not only aligns with global sustainability goals but also meets the rising consumer demand for environmentally responsible electronics. As wire harnesses become more integrated with smart technologies, their role will evolve, potentially incorporating advanced features like IoT connectivity, ultimately driving the next wave of innovation in the electronics industry.

Related Posts

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

Ultimate Guide to Sourcing the Best Wire Harness Cables: Tips, Trends, and Market Insights for Global Buyers

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production

-

7 Best Wire Harness Cable Innovations Revolutionizing Industry Standards

-

The Ultimate Guide to Choosing the Best Cable Harness for Maximum Efficiency

-

How to Optimize Wire Harness Engineering for Enhanced Efficiency and Cost Reduction