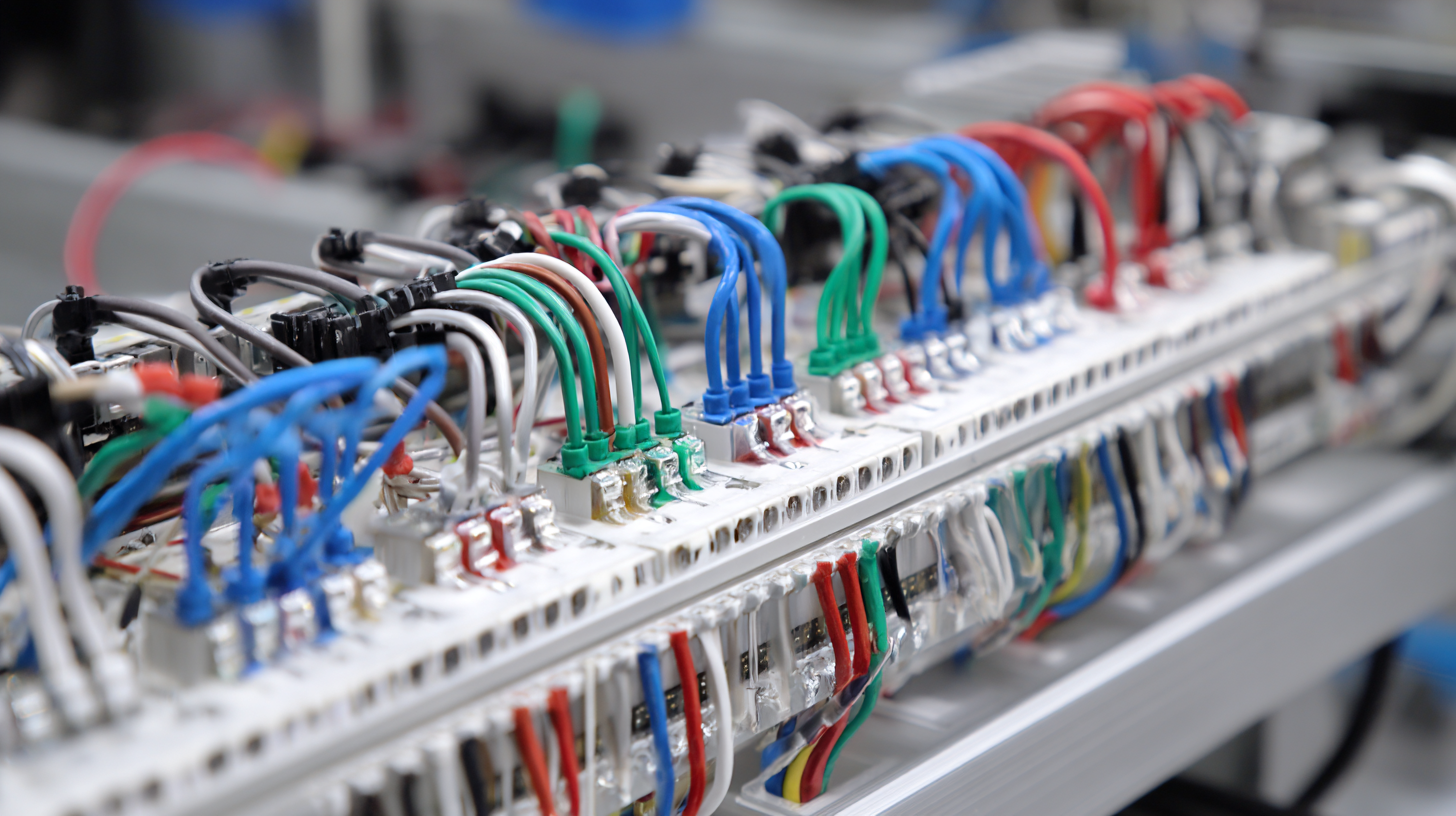

Innovative Solutions for Wire Harness and Cable Assembly in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the significance of wire harness and cable assembly has never been more pronounced. According to a recent report by Market Research Future, the global wire harness market is projected to reach approximately USD 80 billion by 2027, growing at a CAGR of 4.5% over the forecast period. This growth underscores the increased reliance on complex electrical systems across various industries, including automotive, aerospace, and consumer electronics.

As manufacturers strive for greater efficiency and innovation, the demand for advanced wire harness and cable assembly solutions is surging, necessitating the adoption of new technologies such as automated assembly processes and smart manufacturing techniques. These innovative solutions not only enhance productivity but also improve product reliability and safety, thereby addressing the critical challenges faced by the industry. In this context, exploring the latest trends and technologies in wire harness and cable assembly becomes essential for stakeholders aiming to stay competitive in today’s market.

Innovative Techniques for Optimizing Wire Harness Production Efficiency

In modern manufacturing, optimizing wire harness production efficiency is crucial for meeting the demands of a rapidly evolving market. Industry reports indicate that manufacturers can achieve up to 30% reduction in production time by implementing innovative techniques such as automated assembly processes and advanced material handling systems. These strategies not only streamline workflows but also minimize the risk of human error, significantly enhancing overall productivity.

One effective tip for increasing efficiency in wire harness production is to adopt modular designs that allow for flexible configuration in assembly processes. By utilizing standardized components and connectors, manufacturers can simplify the assembly process, reducing setup times between projects. Additionally, integrating real-time data analytics into production lines enables manufacturers to identify bottlenecks quickly, facilitating timely adjustments that optimize throughput.

Another strategy involves investing in training programs that focus on the latest technologies and manufacturing techniques. According to a report by the International Wire and Cable Symposium, well-trained operators can increase output quality and speed by as much as 25%. Equipping teams with the right knowledge fosters a culture of continuous improvement and innovation, ensuring that wire harness production stays ahead of industry trends.

Innovative Solutions for Wire Harness and Cable Assembly Efficiency

This bar chart illustrates the production efficiency in wire harness manufacturing across different techniques. The data represents the average production time (in hours) required per unit for various innovative techniques implemented in modern manufacturing.

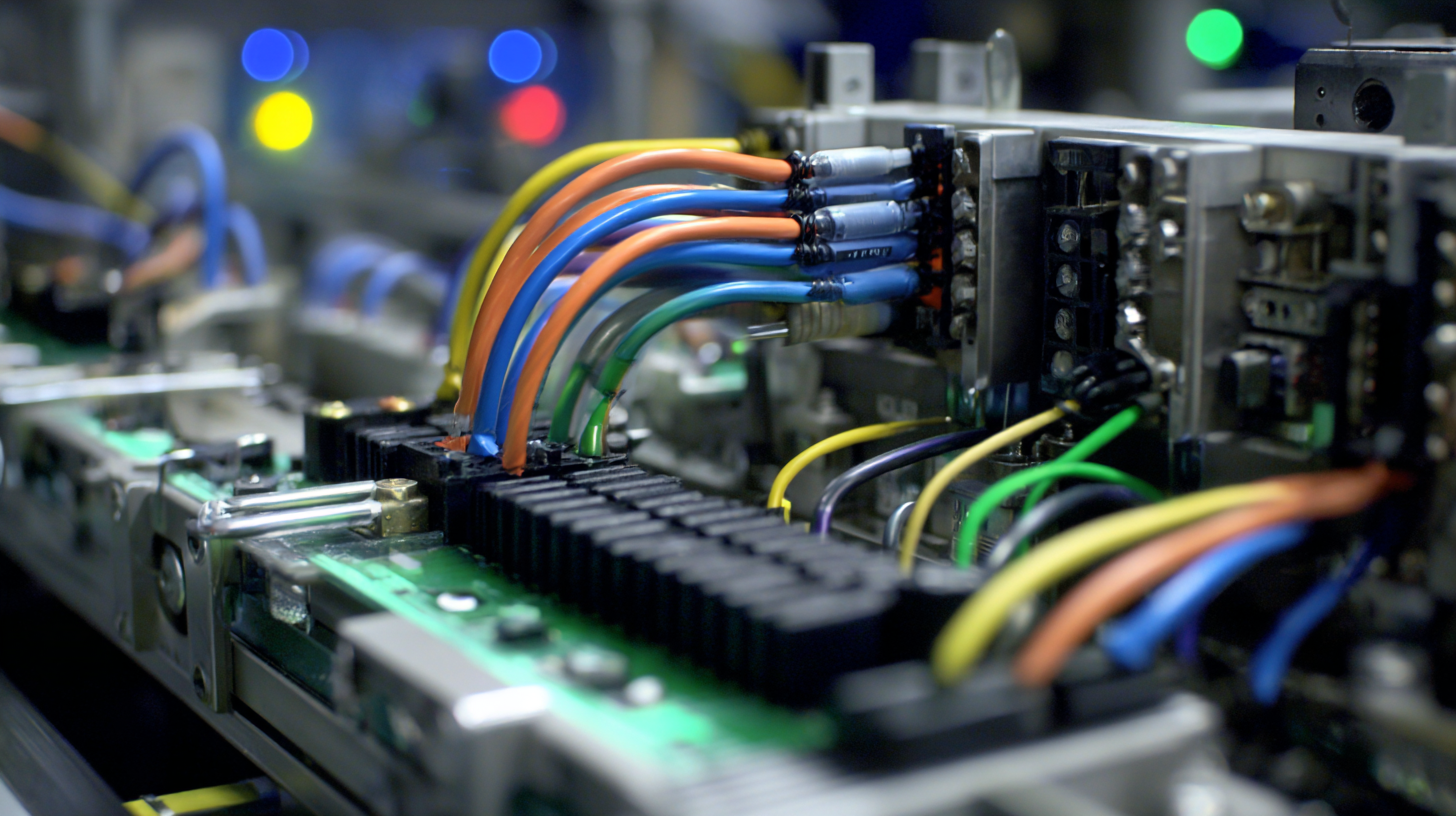

Leveraging Automation Technology to Enhance Cable Assembly Processes

In modern manufacturing, the integration of automation technology into wire harness and cable assembly processes is transforming industry standards. According to a report from MarketsandMarkets, the global market for cable assembly is projected to reach $257.73 billion by 2024, growing at a CAGR of 6.9%. This growth is largely driven by the increasing demand for automation in various sectors, including automotive, aerospace, and consumer electronics. Automation not only enhances productivity but also improves consistency and quality in the manufacturing processes.

Automated solutions such as robotic assembly arms and advanced software systems are streamlining cable assembly operations. For instance, companies implementing automated wire processing technologies have reported up to a 50% reduction in processing time. Additionally, the introduction of AI-driven quality control systems allows manufacturers to detect defects in real-time, significantly decreasing the rate of rework needed. According to a recent study by the Automation Federation, manufacturers who have adopted automation technologies have experienced up to a 30% improvement in output efficiency and resource utilization, showcasing the undeniable benefits of automation in this critical component of modern manufacturing.

Innovative Solutions for Wire Harness and Cable Assembly in Modern Manufacturing - Leveraging Automation Technology to Enhance Cable Assembly Processes

| Process Step | Description | Technology Used | Efficiency Improvement (%) |

|---|---|---|---|

| Material Preparation | Cutting and stripping wires to specific lengths. | Automated Wire Cutting Machines | 25% |

| Assembly | Connecting wires and terminals in predefined configurations. | Robotic Assembly Systems | 40% |

| Quality Control | Testing assembled cables for electrical integrity. | Automated Testing Equipment | 30% |

| Packaging | Final packaging of wire harnesses for shipment. | Automated Packaging Systems | 20% |

Integrating Industry 4.0 Solutions in Wire Harness Manufacturing

The integration of Industry 4.0 solutions in wire harness manufacturing marks a transformative shift in the way components are designed, produced, and assembled. By leveraging advanced technologies such as the Internet of Things (IoT), artificial intelligence, and automation, manufacturers can enhance productivity and ensure precision in their operations. Real-time data analytics allow for continuous monitoring of production processes, leading to quicker identification of inefficiencies and a reduction in downtime.

Moreover, the adoption of smart manufacturing techniques facilitates customization and flexibility within the wire harness sector. With interconnected machines and systems, manufacturers can quickly adapt to changing consumer demands while maintaining high-quality standards. Additionally, the use of robotics and automation not only accelerates the assembly process but also improves safety by minimizing human intervention in hazardous tasks. These innovations collectively contribute to a more streamlined and efficient manufacturing workflow, positioning companies to meet the challenges of a rapidly evolving marketplace.

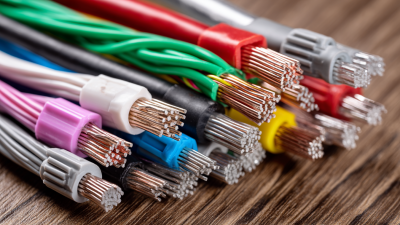

Sustainable Materials and Practices for Eco-Friendly Cable Solutions

In the ever-evolving landscape of modern manufacturing, the drive towards sustainability has significantly influenced innovations in wire harness and cable assembly production. Manufacturers are now focusing on eco-friendly materials and practices that not only reduce environmental impact but also enhance the efficiency of their operations. By incorporating sustainable materials, companies can minimize waste and energy consumption, while ensuring their products meet the increasing demand for environmentally responsible solutions.

As we look towards the future, the market growth for concrete repair systems, projected to rise from $11.1 billion in 2024 to $16.74 billion by 2031, showcases a parallel interest in sustainability within construction practices. This growth underscores the importance of adopting innovative and eco-friendly techniques in both cable assembly and wider manufacturing processes.

Tip: When selecting materials for cable assemblies, consider biodegradable options or those that are easily recyclable to reduce your carbon footprint.

Additionally, engaging in life cycle assessments can help identify areas where improvements can be made, ensuring your operations are as eco-efficient as possible.

Tip: Collaborate with suppliers who prioritize sustainability in their manufacturing processes to enhance your overall eco-friendly credentials.

Data-Driven Approaches to Improve Quality Control in Cable Assemblies

In modern manufacturing, the integration of data-driven approaches has become pivotal in enhancing quality control for wire harness and cable assemblies. According to a recent report by MarketsandMarkets, the global market for wire harnesses is expected to reach $68.5 billion by 2025, reflecting an increasing demand for precision and reliability in manufacturing processes. Leveraging advanced analytics enables manufacturers to monitor production metrics in real-time, identifying defects and inefficiencies before they escalate into costly errors.

Moreover, the introduction of machine learning algorithms in manufacturing settings has shown a potential reduction in defect rates by up to 30%. By analyzing historical data, these algorithms can predict potential failures, allowing for proactive adjustments in manufacturing workflows. Additionally, a study from Deloitte reveals that organizations employing data analytics experience approximately a 15% increase in operational efficiency, underscoring the need for companies to adopt these innovative solutions. As the wire harness and cable assembly sector evolves, embracing data-driven methodologies will be crucial for maintaining competitive advantage and ensuring product quality.

Related Posts

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

7 Essential Tips for Sourcing the Best Harness Cable Assembly in 2024

-

Ultimate Guide to Sourcing the Best Wire Harness Cables: Tips, Trends, and Market Insights for Global Buyers

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production

-

7 Best Wire Harness Cable Innovations Revolutionizing Industry Standards

-

How to Choose the Right Cable Assembly Wire Harness for Your Project