How to Optimize Wire Harness Engineering for Enhanced Efficiency and Cost Reduction

In today's fast-paced manufacturing environment, optimizing wire harness engineering is crucial for enhancing efficiency and driving cost reduction. According to a recent industry report by Allied Market Research, the global market for wire harnesses is projected to reach $61.7 billion by 2027, with a CAGR of 6.3%. This growth underscores the importance of adopting advanced engineering practices to meet rising demand without sacrificing quality.

Manufacturers face increasing pressure to deliver high-performance wire harnesses while minimizing errors and waste. Leveraging digital tools and best practices in wire harness engineering not only streamlines production processes but also reduces lead times and costs, ultimately fostering competitiveness in a crowded marketplace.

As technological advancements continue to reshape the industry, staying ahead requires a commitment to continuous improvement and innovation in wire harness design and assembly.

Understanding the Basics of Wire Harness Engineering for Efficiency Gains

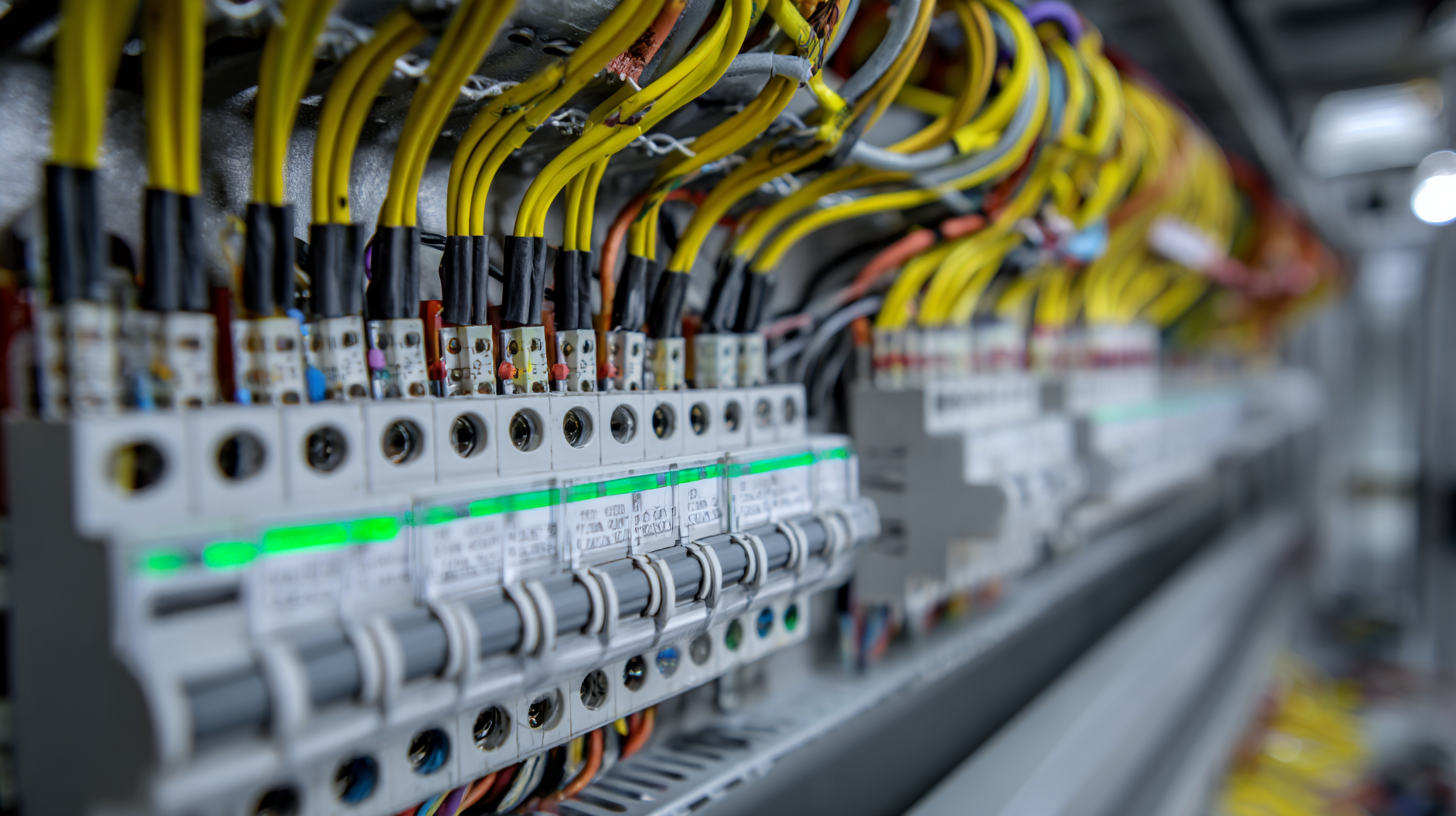

Wire harness engineering is a critical component in modern design and manufacturing, significantly impacting efficiency and cost reduction. Understanding the basics of wire harness engineering begins with recognizing its role in electrical systems. A well-designed wire harness minimizes weight, space, and installation time, while ensuring reliability. According to a recent industry report, optimizing wire harness layouts can lead to a 20% reduction in production time and a 15% decrease in material costs. This efficiency is crucial as manufacturers strive to remain competitive in a rapidly evolving market.

Moreover, incorporating the latest advancements in motion control technology can enhance the design of wire harnesses. Engineers must comprehend the fundamental principles of motion control to effectively integrate these systems into their wire harness designs. Reports suggest that informed decision-making in this area can lead to performance improvements of up to 25%, driving overall project success. By focusing on simplicity and functionality, engineers can streamline their processes and achieve substantial gains, positioning their products for long-term viability in the marketplace.

Wire Harness Engineering Optimization: Efficiency Gains and Cost Reduction

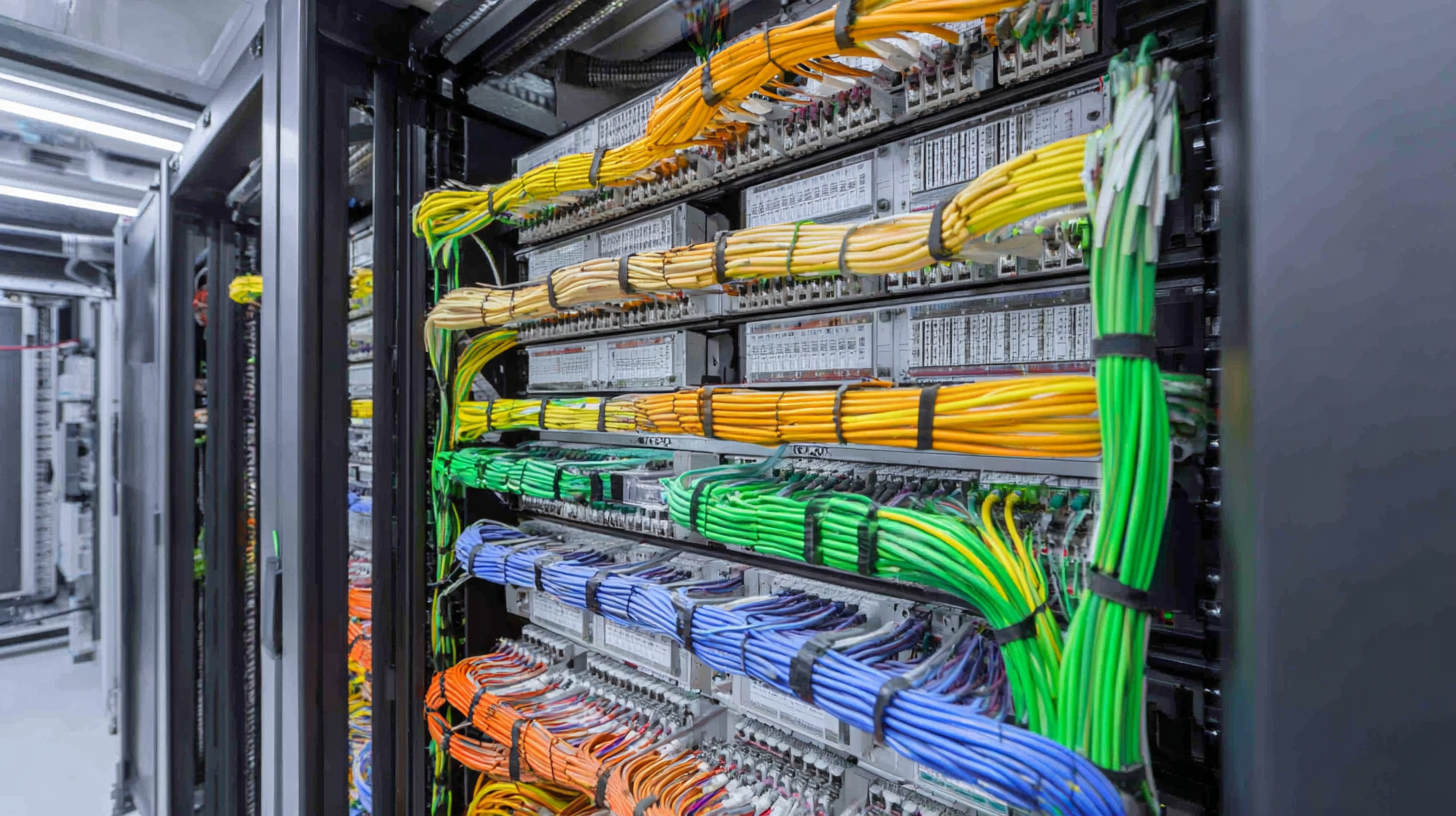

Key Strategies for Streamlining Design Processes in Wire Harness Development

In wire harness development, streamlining the design processes is crucial for enhancing efficiency and reducing costs. One key strategy is the integration of Design for Manufacture (DFM) principles, which focus on simplifying designs to alleviate complexities commonly encountered in automotive production. This approach not only minimizes manufacturing challenges but also supports the growing demand for electric vehicle (EV) innovations, potentially fostering greater market growth. For instance, the Mexico automotive wiring harness market is projected to expand significantly, from $684.62 million in 2024 to $1,054.69 million by 2035, highlighting the critical need for optimized engineering practices.

Tips for streamlining design processes include employing advanced Electronic Design Automation (EDA) tools to improve the PCB-to-wire harness design integration. This can greatly reduce the fragmentation caused by different tools in the design workflow. Additionally, effective management of engineering change orders (ECOs) is essential. Given that managing ECOs poses substantial challenges in modern vehicle development, implementing a centralized system can lead to smoother transitions and quicker approvals, ultimately enhancing the overall efficiency in harness design.

Another vital strategy is to focus on centralized electronic and software architectures for commercial vehicles. By shifting towards a software-centric approach, manufacturers can better handle the complexities of modern wire harness designs and unlock new opportunities for innovation and efficiency.

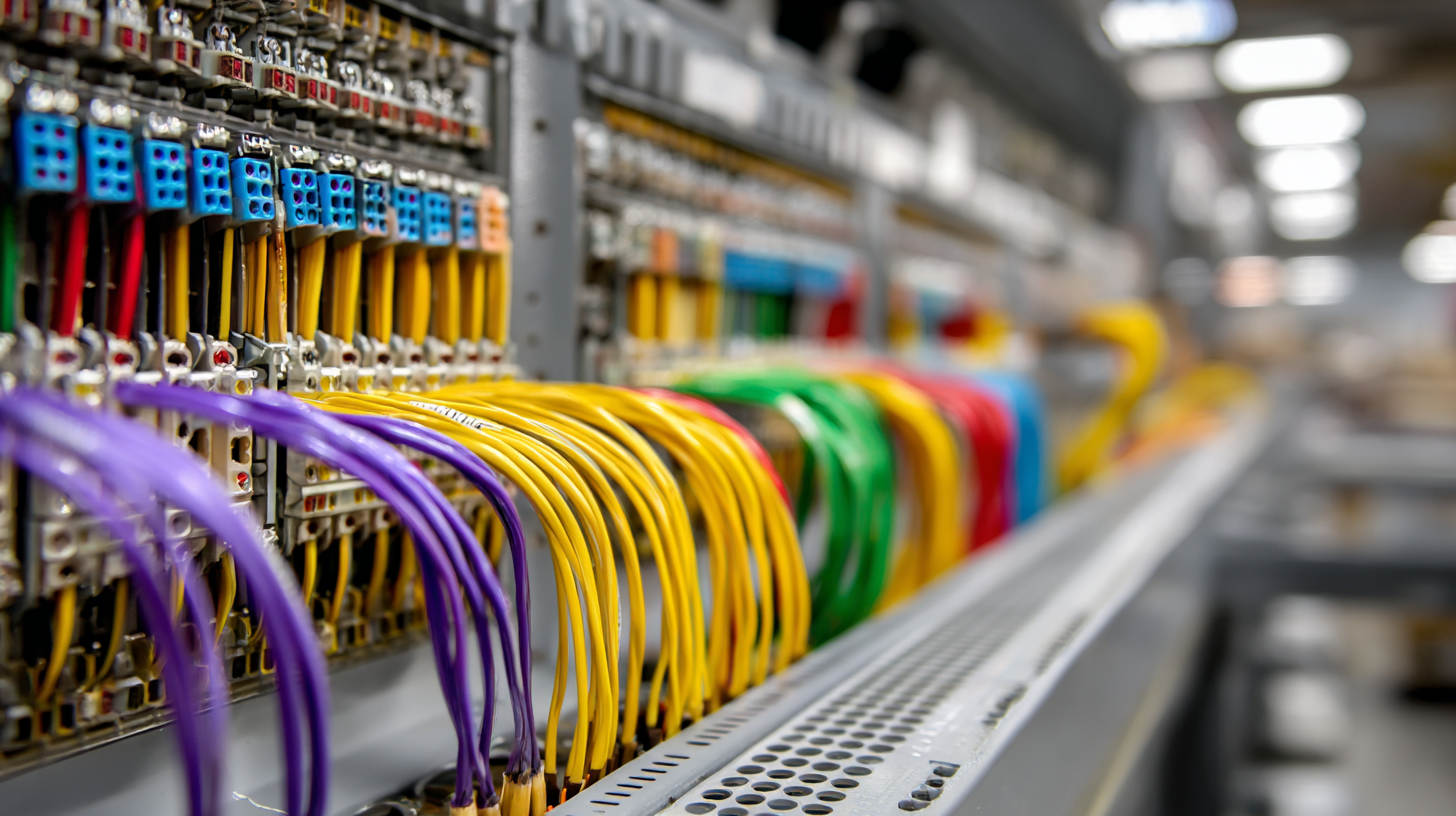

Utilizing Advanced Materials and Technologies for Cost Reduction

In the realm of wire harness engineering, the utilization of

advanced materials and technologies plays a pivotal role in driving both

efficiency and cost reduction. Recent industry reports indicate that switching from traditional copper wiring

to lightweight alternatives such as aluminum or composite materials can lead to significant cost savings, potentially up to

30%, while also enhancing performance. These advanced materials not only

reduce the weight of the harness, contributing to improved fuel efficiency in automotive applications, but they also offer

better resistance to environmental factors, leading to increased durability and lifespan.

Furthermore, the integration of cutting-edge technologies such as automation and sophisticated design software is transforming

wire harness manufacturing. A study by the International Society of Automation revealed

that companies implementing these technologies have experienced productivity boosts of over 40%,

which directly correlates to reduced labor costs and increased throughput. By optimizing the engineering process with tools

such as 3D modeling and simulation, manufacturers can identify potential

issues early in the design phase, minimizing costly rework and ensuring a more efficient production cycle. Embracing

these advancements not only streamlines operations but also aligns with the growing trend towards sustainable manufacturing practices.

Best Practices for Testing and Quality Assurance in Wire Harness Production

Testing and quality assurance are critical components in wire harness production, directly influencing both performance and reliability. Implementing rigorous testing protocols throughout the production process helps identify issues early, potentially saving considerable costs associated with rework and material waste. One effective strategy is to employ automated testing systems that can quickly assess parameters like continuity, insulation resistance, and load performance. By incorporating these technologies, manufacturers can achieve higher repeatability and accuracy in their tests, ensuring that every harness meets the required specifications.

Testing and quality assurance are critical components in wire harness production, directly influencing both performance and reliability. Implementing rigorous testing protocols throughout the production process helps identify issues early, potentially saving considerable costs associated with rework and material waste. One effective strategy is to employ automated testing systems that can quickly assess parameters like continuity, insulation resistance, and load performance. By incorporating these technologies, manufacturers can achieve higher repeatability and accuracy in their tests, ensuring that every harness meets the required specifications.

In addition to automated testing, establishing a robust quality assurance framework can further enhance overall efficiency. This includes creating standardized procedures for inspections and fostering a culture of quality within the team. Regular training sessions for employees on best practices in production and quality checks can significantly reduce human error and improve attention to detail. Moreover, utilizing data analysis tools to track test results and production metrics allows teams to pinpoint recurring issues and streamline processes. By focusing on these best practices, wire harness manufacturers can elevate both the quality of their products and their operational efficiency.

Collaborative Approaches to Enhance Communication and Efficiency in Teams

Effective communication is vital in wire harness engineering, particularly when aiming for enhanced efficiency and cost reduction. Collaborative approaches can bridge gaps between team members, fostering a culture of openness where ideas and feedback flow freely. Utilizing tools like real-time project management software can streamline workflows and keep everyone aligned on objectives. Regular meetings and brainstorming sessions encourage all team members, from designers to production staff, to share insights and address potential challenges proactively.

Additionally, cross-functional teams can significantly boost collaboration. By integrating specialists from various disciplines, engineers can gain diverse perspectives that enhance problem-solving capabilities. This collective intelligence can lead to innovative solutions that streamline the design and production processes of wire harnesses, ultimately driving down costs. Emphasizing teamwork and clear communication not only improves project outcomes but also strengthens relationships between departments, enabling a more responsive and agile engineering environment.

How to Optimize Wire Harness Engineering for Enhanced Efficiency and Cost Reduction

| Dimension | Current State | Optimized State | Impact on Efficiency | Cost Reduction |

|---|---|---|---|---|

| Design Collaboration | Limited interaction among teams | Cross-functional design sessions | 20% faster design cycles | 15% reduction in redesign costs |

| Material Selection | Standard materials chosen | Advanced material analysis | Improved durability by 30% | 10% savings on material costs |

| Production Process | Manual assembly methods | Automated assembly lines | 25% increase in production speed | 30% reduction in labor costs |

| Quality Control | Periodic inspections | Continuous monitoring systems | 10% decrease in defect rates | 5% reduction in warranty costs |

Related Posts

-

How to Choose the Best Wire Harness Wire for Future Tech Trends in 2025

-

Comparing Different Approaches to Wire Harness Manufacturing Techniques

-

The Ultimate Guide to Choosing the Best Cable Harness for Maximum Efficiency

-

Ultimate Guide to Sourcing the Best Wire Harness Cables: Tips, Trends, and Market Insights for Global Buyers

-

7 Best Wire Harness Cable Innovations Revolutionizing Industry Standards

-

Global Sourcing of Premium Electronic Wire Harnesses: China's Quality Leads the Way