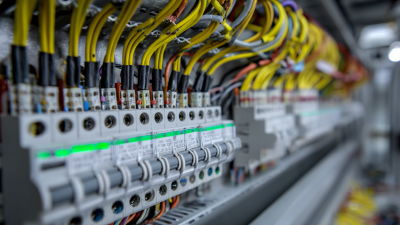

Revolutionizing Connectivity: The Future of Cable and Wire Harness Solutions for Modern Industries

As industries evolve and technology advances, the demand for innovative solutions in connectivity has never been more critical. Cable and wire harness systems play a pivotal role in various sectors, from automotive to aerospace, and their significance is underscored by a recent market report by MarketsandMarkets, which forecasts that the global wire harness market will grow from $64.3 billion in 2020 to $86.9 billion by 2025, at a CAGR of 6.1%. This growth is driven by the increasing complexity of electrical systems in modern vehicles, industrial machinery, and consumer electronics, necessitating highly efficient and reliable cable and wire harness solutions. By embracing new materials, advanced manufacturing techniques, and smart technologies, industries can revolutionize their connectivity frameworks, ensuring enhanced performance, safety, and sustainability in their operations. As we delve into the future of cable and wire harness solutions, it is essential to explore how these innovations can redefine connectivity across various industrial landscapes.

Emerging Trends in Cable and Wire Harness Technology for a Connected Future

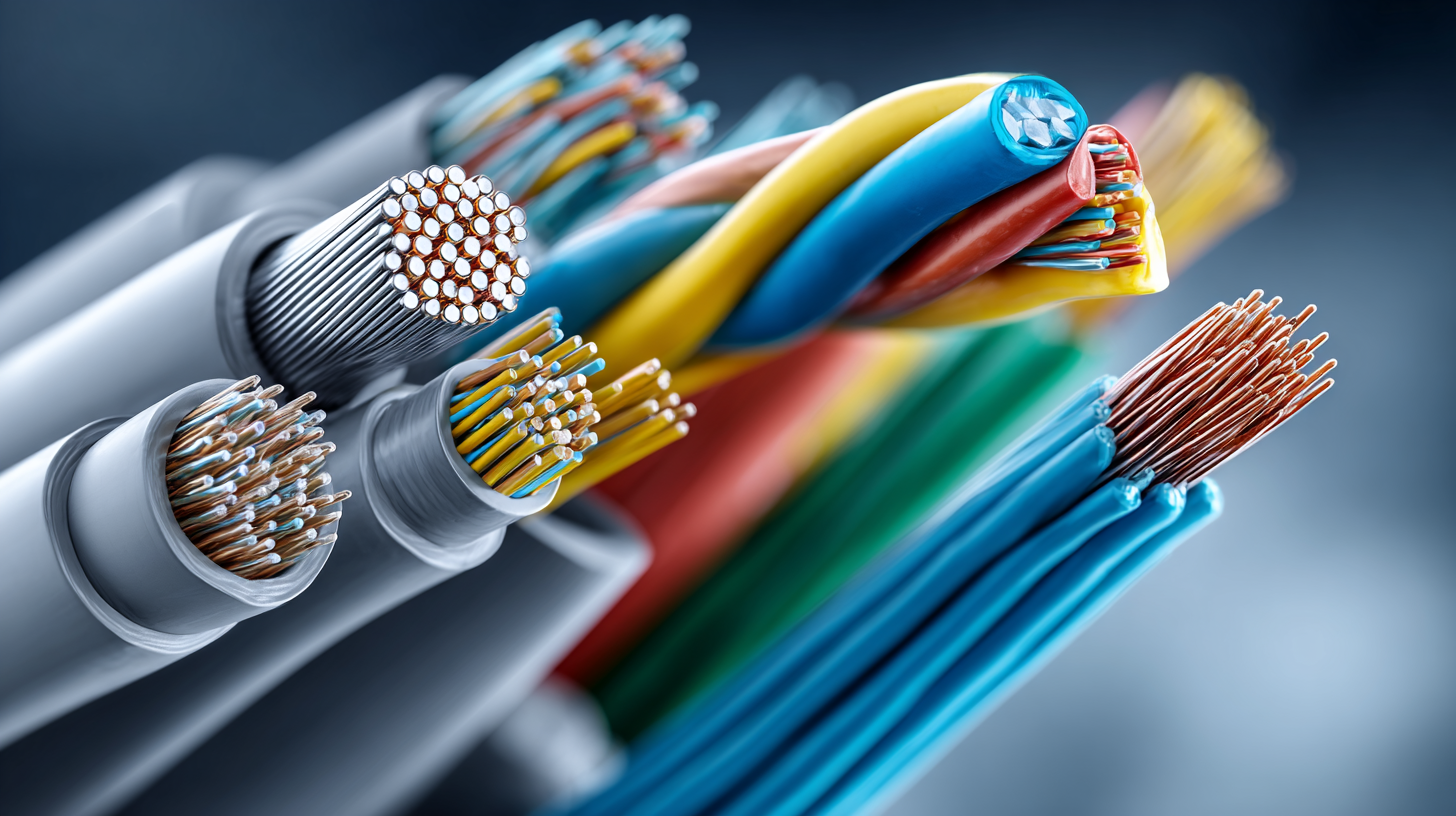

The rapid evolution of technology has propelled the demand for innovative cable and wire harness solutions across various industries. According to a recent report from MarketsandMarkets, the global wire harness market is expected to grow from $55.93 billion in 2022 to $78.31 billion by 2027, at a CAGR of 6.7%. This shift is driven by the increasing adoption of automation and the Internet of Things (IoT), which require highly efficient and reliable connectivity solutions to support complex systems. Manufacturers are now focusing on creating lighter, more flexible, and durable harness configurations to meet these emerging needs.

Furthermore, the rise of electric vehicles (EVs) and renewable energy systems has significantly influenced cable and wire harness technologies. The International Energy Agency projects that the number of electric cars on the road could reach 145 million by 2030, underscoring a critical need for advanced wiring solutions that enhance energy efficiency and minimize weight. As a result, manufacturers are exploring new materials such as lightweight composites and integrating smart technologies, allowing for real-time monitoring and diagnostics, thereby revolutionizing connectivity in modern industries.

Emerging Trends in Cable and Wire Harness Technology

This chart illustrates the projected growth in market demand for various industries relying on cable and wire harness solutions. The data forecasts increasing demand, particularly in sectors like IoT devices and electric vehicles, crucial for enhancing connectivity in modern applications.

Impact of Industry 4.0 on Cable and Wire Harness Design and Manufacturing

The advent of Industry 4.0 has dramatically transformed the landscape of cable and wire harness design and manufacturing. By integrating advanced technologies such as IoT, artificial intelligence, and automation, manufacturers can achieve unprecedented levels of efficiency and precision. This digital revolution allows for real-time monitoring and data analytics, which not only streamlines production processes but also enhances quality control. As a result, companies can respond more swiftly to market demands and reduce waste, ultimately leading to more sustainable practices within the industry.

Moreover, the design phase benefits significantly from the tools and technologies driven by Industry 4.0. Engineers can utilize simulations and digital twins to test and refine cable harness configurations in virtual environments before physical production begins. This leads to greater innovation, as complex designs can be iterated quickly and cost-effectively. Additionally, the flexibility provided by modular designs enables manufacturers to adapt more readily to the unique requirements of various applications, from automotive to aerospace, ensuring that their connectivity solutions remain relevant in an ever-evolving industrial landscape.

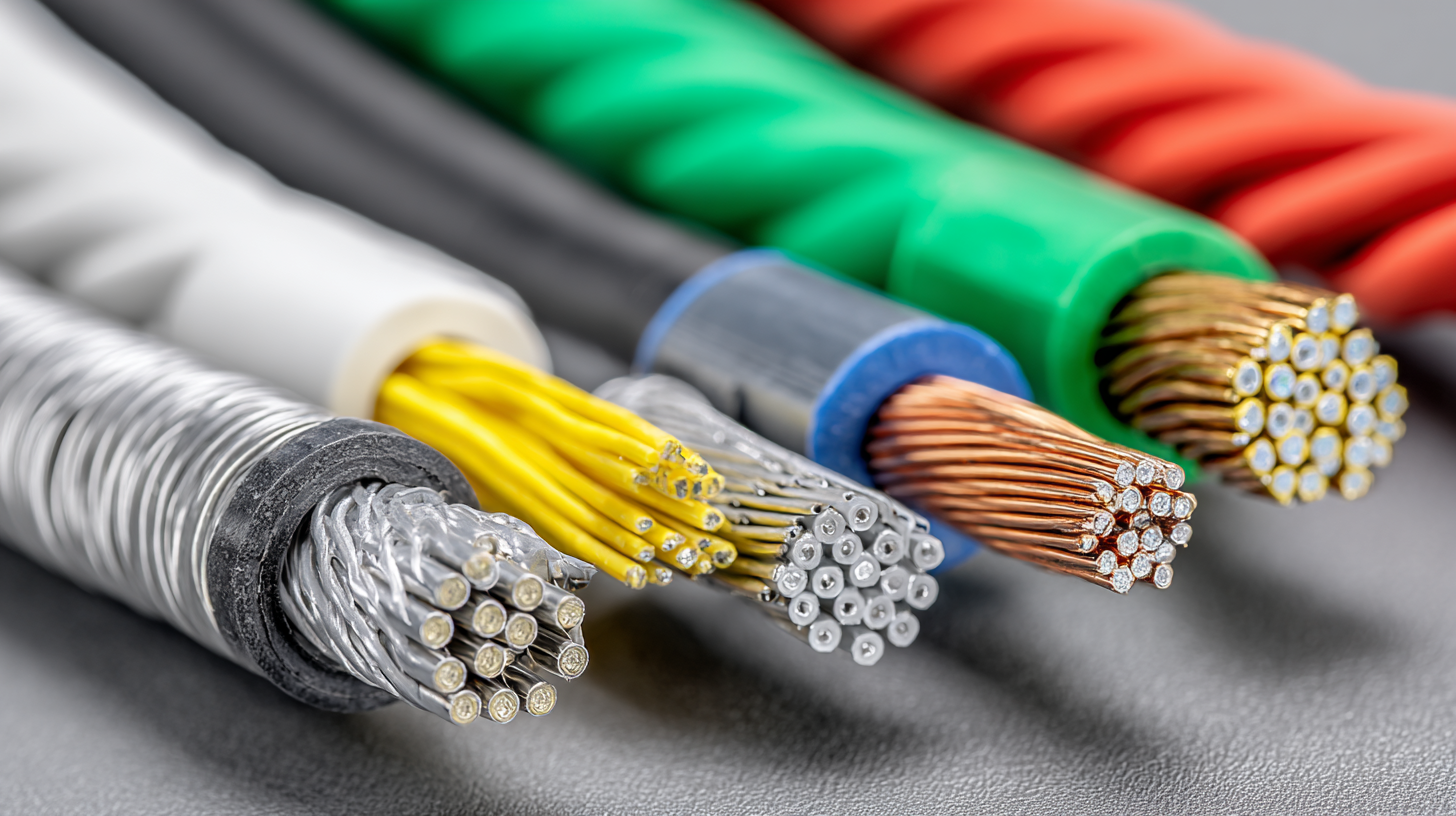

Sustainability in Cable Solutions: Eco-Friendly Materials and Practices

As industries evolve, the demand for sustainable cable and wire harness solutions is becoming paramount. Eco-friendly materials are at the forefront of this revolution, with companies increasingly opting for biodegradable plastics and recycled metals in their products. These innovative approaches not only reduce environmental impact but also meet the growing consumer demand for greener choices. The integration of renewable resources into cable manufacturing processes showcases a commitment to sustainability that resonates with environmentally conscious businesses.

Tip: When selecting cable solutions, prioritize suppliers who emphasize sustainable practices in their manufacturing processes. Look for certifications that verify the use of eco-friendly materials to ensure your choices contribute positively to environmental conservation.

Sustainability also extends to production methods. Companies are adopting energy-efficient manufacturing practices and minimizing waste through improved designs. This not only lessens the carbon footprint but also enhances operational efficiency. By embracing these practices, businesses can significantly decrease their environmental impact while positioning themselves as leaders in sustainability.

Tip: Consider conducting an audit of your current cable solutions to identify areas where more sustainable options can be integrated, potentially leading to cost reductions over time while promoting eco-friendliness.

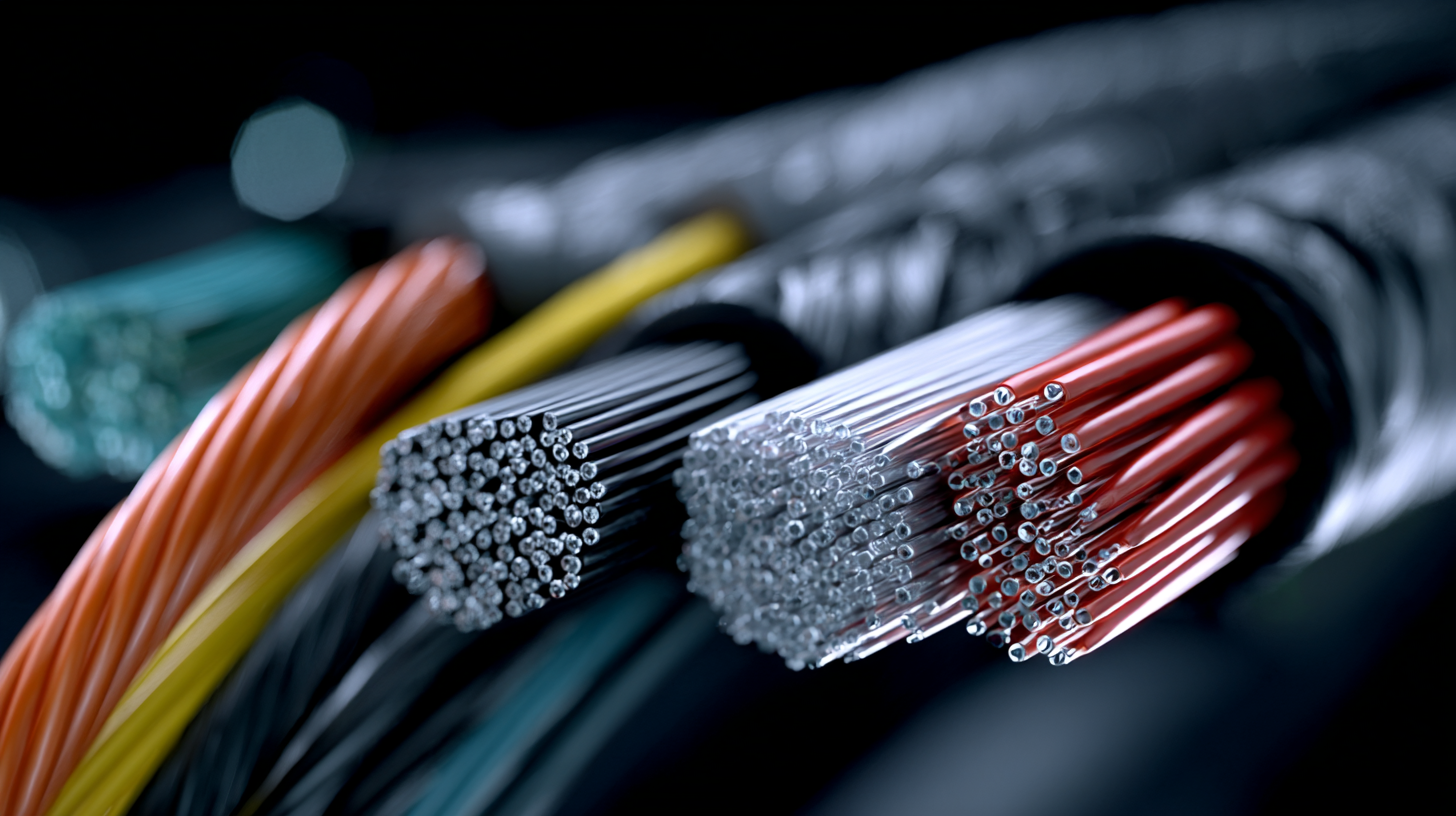

Maximizing Efficiency in Modern Industries through Advanced Wiring Systems

The future of cable and wire harness solutions is essential for maximizing efficiency in modern industries, particularly in sectors like manufacturing and energy. Recent studies highlight the integration of advanced wiring systems with cutting-edge technologies such as artificial intelligence and machine learning. For instance, a comprehensive review focused on machine learning techniques reveals that optimizing electrical and electronic engineering projects can enhance operational efficiency by up to 30%. As these technologies evolve, they can revolutionize how wiring systems are designed and implemented, paving the way for smarter, more efficient production processes.

In the context of energy transition and sustainable development, the role of effective wiring systems becomes even more crucial. Reports show that integrating advanced solutions in renewable energy infrastructure—like solar and wind—can increase energy efficiency significantly. For example, hybrid renewable energy systems that incorporate sophisticated wiring techniques can reduce energy loss during transmission, translating to better performance and cost savings. The ongoing digitalization across industries further emphasizes the need for advanced wiring solutions, which facilitate improved communication and connectivity among devices, leading to real-time monitoring and enhanced decision-making capabilities.

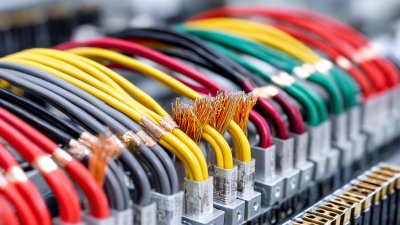

Market Insights: Projected Growth and Innovations in the Cable Industry by 2025

The cable and wire harness solutions market is on the cusp of significant transformation, driven by advancements in technology and increased demand across various industries. In the U.S., the utility wires and cables market is poised for growth, expected to rise from $9.02 billion in 2025 to $13.26 billion in the following years. This reflects a broader trend in the cable industry, where innovative materials and manufacturing processes are being developed to enhance performance and sustainability.

As industries adapt to new challenges and opportunities, the power and control cable sectors are also undergoing substantial changes. The North American market for control cables, in particular, is projected to see robust growth, driven by innovations in cable design and increased applications in renewable energy and automation. By 2034, the medium voltage wire and cable market is anticipated to exceed $64.7 billion, showcasing a compound annual growth rate (CAGR) of 7.3% from 2025. This growth underscores the pivotal role of cable solutions in modern connectivity and infrastructure development as industries move towards more interconnected systems.

Related Posts

-

Global Sourcing of Premium Electronic Wire Harnesses: China's Quality Leads the Way

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production

-

How to Choose the Right Cable Assembly Wire Harness for Your Project

-

5 Essential Tips for Choosing the Best Wire Harness Manufacturing Equipment

-

How to Optimize Wire Harness Engineering for Enhanced Efficiency and Cost Reduction

-

Ultimate Guide to Sourcing the Best Wire Harness Cables: Tips, Trends, and Market Insights for Global Buyers