Revolutionizing Wire Harness Manufacturing with Advanced Automation Technologies in 2024

The wire harness manufacturing industry is undergoing a transformative shift thanks to advanced automation technologies in 2024. As the demand for increasingly complex wiring solutions rises, manufacturers are turning to automation to enhance efficiency and precision. According to a recent report by MarketsandMarkets, the global wire harness market is projected to reach $57.64 billion by 2026, driven by innovations and the integration of smart technologies. This illustrates a significant opportunity for businesses to leverage automation, reducing errors and increasing production speed while meeting consumer demands.

Industry expert Dr. Emily Carter, a leading figure in automation within the wire harness manufacturing sector, emphasizes the importance of this evolution: "The integration of advanced automation technologies represents not just an operational upgrade; it's a fundamental shift in the way we design and produce wire harnesses. This will not only streamline processes but also open new avenues for innovation." As the industry prepares for this technological overhaul, manufacturers who embrace these advancements are well-positioned to thrive in a competitive landscape, redefine operational standards, and improve overall product quality. The future of wire harness manufacturing is not merely about meeting requirements but setting new benchmarks for excellence through automation.

Understanding Advanced Automation Technologies in Wire Harness Manufacturing

The wire harness manufacturing industry is undergoing significant transformation as companies adopt advanced automation technologies to enhance efficiency and precision. According to a report by MarketsandMarkets, the global automation market is expected to reach $290 billion by 2024, reflecting a compound annual growth rate (CAGR) of 9.2%. This surge is largely driven by the increasing complexity of wire harness assemblies and the need for cost-effective production solutions. Automation technologies such as robotics, AI, and the Internet of Things (IoT) are being integrated to streamline processes, minimize human errors, and maintain high-quality standards.

One of the most impactful advancements in the sector is the implementation of flexible automation systems, which allow manufacturers to adapt quickly to varying production requirements. This flexibility not only increases throughput but also reduces lead times, enabling companies to respond swiftly to market demands. According to a study by Frost & Sullivan, manufacturers that implement automation can achieve up to a 30% increase in productivity. As wire harness manufacturers embrace these advanced technologies, they position themselves to meet the challenges of the future while driving innovation and sustainability within the industry.

Key Benefits of Implementing Automation in Wire Harness Production

In the rapidly evolving landscape of wire harness manufacturing, the integration of

advanced automation technologies is proving to be transformative.

According to a recent industry report by MarketsandMarkets, the global automation market in manufacturing is projected to

grow from $173.89 billion in 2020 to $418.36 billion by

2026, emphasizing the critical role automation plays in enhancing operational efficiency. By implementing automated systems,

manufacturers can significantly reduce production time, minimize human error, and streamline workflows, which collectively

contribute to higher productivity levels.

One of the key benefits of automation in wire harness production is the capability for greater precision and

consistency. A study conducted by the International Society of Automation highlights

that automated processes can increase production consistency by up to 90%, which is

crucial in industries requiring high reliability, such as automotive and aerospace. Furthermore, automation not only boosts

quality control but also allows companies to adapt more swiftly to fluctuating market demands by utilizing

data analytics for better resource allocation and schedule optimization,

ultimately driving substantial cost savings.

Step-by-Step Guide to Integrating Advanced Automation into Your Manufacturing Process

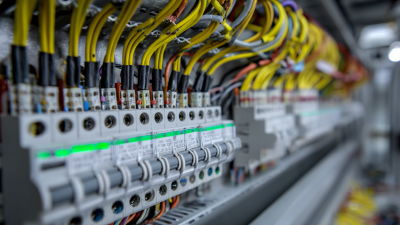

Integrating advanced automation technologies into wire harness manufacturing can significantly enhance efficiency and precision. The first step involves assessing your current manufacturing processes to identify bottlenecks and areas for improvement. Conduct a thorough analysis of workflow, cycle times, and production rates. This information will serve as a baseline for measuring the effectiveness of automation solutions.

Next, it's crucial to choose the right automation technologies that align with your manufacturing objectives. Consider implementing robotic arms for assembly tasks, automated guided vehicles (AGVs) for material handling, and advanced software systems for real-time monitoring and analytics. Collaborating with technology providers during this phase can help tailor solutions to your specific needs, ensuring a smooth integration. Training employees on these new systems is essential for maximizing productivity and ensuring a seamless transition to automated processes.

Finally, continuously monitor the performance of your automated systems to drive ongoing improvements. Establish metrics that measure efficiency, error rates, and downtime, and analyze these regularly to identify further optimization opportunities. By embracing this step-by-step approach, manufacturers can successfully revolutionize their wire harness production lines while paving the way for future innovations.

Innovative Solutions: Tools and Systems for Modern Wire Harness Automation

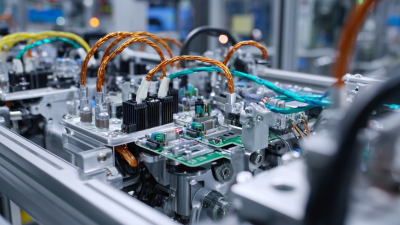

The wire harness manufacturing industry is on the cusp of a transformative wave, driven by advanced automation technologies. According to a recent report from MarketsandMarkets, the global market for automation in manufacturing is projected to reach $214 billion by 2026, with a significant portion attributed to innovative solutions tailored for wire harness production. Automation tools such as robotic assembly systems and AI-driven quality control are leading this revolution, minimizing time and errors, and maximizing efficiency.

In 2024, manufacturers will increasingly adopt smart technologies, such as the Internet of Things (IoT) and machine learning, to streamline operations. These systems are not only enhancing production speeds but also providing real-time data analytics that can predict maintenance needs, reducing downtime. A study by Automation World indicated that companies implementing these advanced solutions could see productivity increases of up to 30% within the first year. As the industry evolves, embracing these innovative tools and systems will be crucial for companies aiming to stay competitive in a fast-paced market.

Revolutionizing Wire Harness Manufacturing with Advanced Automation Technologies in 2024

This chart illustrates the projected investment in various automation technologies for wire harness manufacturing in 2024. As the industry moves towards advanced automation, significant funds are allocated to robotic assembly and automated testing, showcasing a commitment to innovation and efficiency.

Future Trends: The Evolution of Automation in the Wire Harness Industry by 2024

As the wire harness industry looks toward 2024, advanced automation technologies are set to revolutionize manufacturing processes. With the global wire harness market projected to expand significantly, driven by increased automotive sales, the integration of artificial intelligence (AI) is playing a pivotal role in shaping operational efficiencies. AI not only enhances production speed but also improves accuracy in wire harness assembly, reducing waste and minimizing errors. By leveraging machine learning and data analytics, manufacturers can optimize their workflows and respond agilely to market demands.

Future trends indicate a shift toward more sophisticated automated solutions, including collaborative robots and predictive maintenance systems. These innovations promise to empower workforce efficiencies while addressing the complexity of modern wire harness designs. As the automotive sector increasingly adopts software-defined vehicles, the need for advanced electrical distribution systems becomes critical, prompting further investment in automation technologies. The focus on sustainability and innovation within the manufacturing landscape suggests that by 2024, the wire harness industry will be characterized by smarter, more responsive production methods that align with evolving market and environmental demands.

Revolutionizing Wire Harness Manufacturing with Advanced Automation Technologies in 2024

| Feature | Description | Impact on Industry | Future Outlook |

|---|---|---|---|

| AI Integration | Utilizing machine learning for predictive maintenance. | Reduction in downtime and increased efficiency. | A significant part of manufacturing workflows by 2024. |

| Robotics | Automated assembly lines for wire harness production. | Faster production speeds and improved accuracy. | Increased adoption in the coming years. |

| IoT Technologies | Smart sensors for real-time monitoring. | Enhanced operational visibility and decision-making. | Continuous growth in system integration. |

| Additive Manufacturing | 3D printing of wire harness components. | Customization and reduced material waste. | More adoption and integration with traditional methods. |

| Data Analytics | Analyzing production data for continuous improvement. | Better resource management and cost reduction. | A staple for strategic decisions by 2024. |

Related Posts

-

Exploring the Future of Wire Harness Manufacturing: Innovations That Are Shaping the Industry

-

Exploring Innovations in Wire Harness Manufacturing for the Future of Automotive Technology

-

Comparing Different Approaches to Wire Harness Manufacturing Techniques

-

How to Optimize Wire Harness Engineering for Enhanced Efficiency and Cost Reduction

-

Harness Manufacturing Innovations at China Import and Export Fair in 2025

-

The Future of Harness Assembly Driven by Innovation and Global Demand