How to Successfully Navigate Wire Harness Manufacturing Processes and Challenges

In the intricate world of wire harness manufacturing, navigating the various processes and challenges can determine the success of a project. Experts in the field emphasize the need for precision and efficiency in each step of production. For instance, John Carter, a leading expert in electrical engineering and wire harness design, once remarked, "Understanding the complexities of wire harness manufacturing is crucial for meeting both quality standards and customer expectations." His insights highlight the industry's emphasis on mastering both the technical and logistical aspects required for effective manufacturing.

The dynamic nature of wire harness manufacturing involves multiple components—from material selection and design accuracy to quality assurance and timely delivery. With advancements in technology, manufacturers encounter new challenges, such as adapting to rapidly changing automotive and aerospace standards, which demand innovative solutions and increased flexibility. As companies strive to enhance their production capabilities, the importance of implementing robust processes cannot be overstated. By addressing these challenges head-on, professionals can ensure that their wire harness manufacturing operations remain competitive and successful in a fast-paced market.

Understanding Wire Harness Manufacturing: Key Processes and Techniques

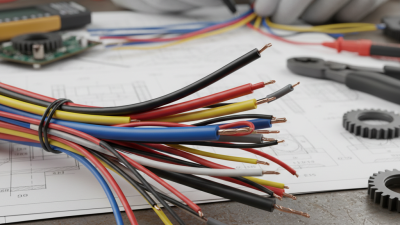

Understanding wire harness manufacturing involves recognizing the critical processes that drive

production efficiency and product quality. The first step in this process is

design and engineering, where the specifications for the wire harness are developed based on

the application requirements. This stage includes creating detailed schematics that outline the wire types, connectors, and assembly methods needed to meet

performance criteria. Advanced software tools are often employed to simulate the wiring configurations and validate design

integrity before moving on to the manufacturing phase.

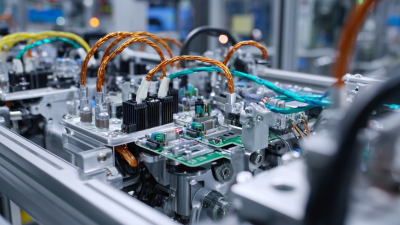

Once the design is finalized, the manufacturing process begins. This typically

includes wire cutting, stripping, and crimping, which are essential for ensuring

reliable electrical connections. Automated machinery plays a significant role in enhancing precision and reducing production time.

Another vital aspect is the assembly process, where the individual components are brought together.

Quality control measures, such as testing for continuity and insulation resistance, are essential throughout the manufacturing to identify and rectify any potential

issues early in the production cycle. By employing efficient production techniques and

stringent quality standards, manufacturers can effectively navigate the challenges

associated with wire harness production.

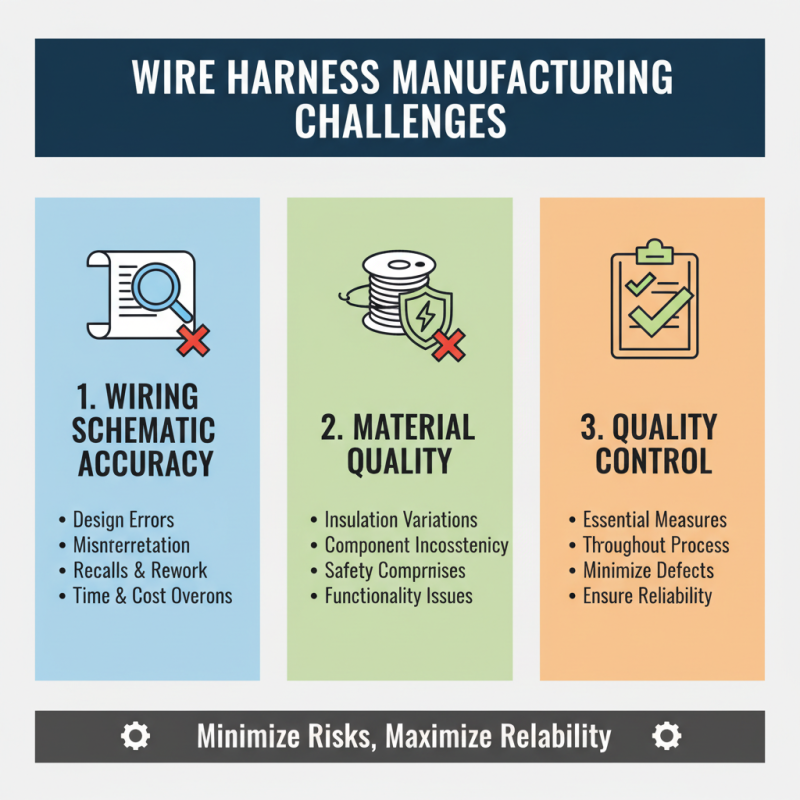

Identifying Common Challenges in Wire Harness Production

Wire harness manufacturing is a complex process that can be fraught with various challenges. One of the most common issues faced during production is ensuring the accuracy of the wiring schematics. Misinterpretations or errors in the design phase can lead to significant recalls and rework, resulting in time delays and increased costs. Additionally, maintaining consistency in wire insulation and material quality is crucial. Variations in these components can compromise the overall safety and functionality of the finished product, making quality control measures essential throughout the manufacturing process.

Another significant challenge is the integration of new technology into existing production lines. As advancements in automation and data analytics emerge, manufacturers often struggle to update their processes without disrupting current operations. This transition requires careful planning and training, as well as the assurance that existing workforce skills align with new technological demands. Moreover, managing supply chain disruptions is vital; fluctuations in supplier reliability can lead to delays in production and increased costs. By proactively identifying these challenges and implementing strategic solutions, manufacturers can enhance their efficiency and product quality while navigating the complexities of wire harness production.

Best Practices for Quality Control in Wire Harness Manufacturing

Quality control is paramount in wire harness manufacturing, where precision and reliability are essential for ensuring optimal performance in various electrical applications. One of the best practices for maintaining quality is implementing a comprehensive inspection system throughout the production process. This includes systematic checks at multiple stages, such as during the selection of raw materials, assembly, and final testing. By adopting a multi-tiered inspection approach, manufacturers can identify potential defects early, reducing the likelihood of costly rework or returns.

Another critical practice is the use of standardized procedures and documentation. Clearly defined work instructions and quality benchmarks foster consistency and allow for better traceability during manufacturing. Regular training sessions for employees on these standards can further enhance product quality, as it ensures that everyone is aligned with the company’s expectations and industry best practices. Additionally, leveraging data analytics for continuous improvement helps in pinpointing recurring issues, ultimately leading to more effective solutions and higher overall quality in wire harness production.

How to Successfully Navigate Wire Harness Manufacturing Processes and Challenges - Best Practices for Quality Control in Wire Harness Manufacturing

| Process Step | Best Practice | Challenges | Quality Control Measures |

|---|---|---|---|

| Design Phase | Use CAD Software | Design Errors | Design Reviews |

| Material Selection | Source Quality Materials | Inconsistent Quality | Material Testing |

| Assembly | Standard Operating Procedures | Human Error | Regular Training |

| Testing | Implement Testing Protocols | Inadequate Testing | Quality Audits |

| Shipping | Proper Packaging | Damage During Transit | Inspection Before Shipping |

Innovative Technologies Transforming Wire Harness Production Processes

As wire harness manufacturing evolves, innovative technologies are playing a pivotal role in enhancing production processes. The rise of automation and advanced robotics has significantly transformed the industry, leading to increased efficiency and precision. According to a report by Research and Markets, the global wire harness market is projected to reach USD 73.89 billion by 2026, demonstrating the growing demand for robust and sophisticated manufacturing methods. The integration of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is enabling manufacturers to optimize workflows and reduce errors, ultimately driving higher quality standards.

To successfully navigate the manufacturing landscape, companies should embrace these innovative technologies. For instance, implementing IoT solutions allows for real-time monitoring of production lines, leading to proactive maintenance and minimized downtime. Additionally, AI-powered analytics can help identify inefficiencies within processes, allowing for data-driven decisions that enhance productivity.

Tips:

1. Invest in training programs to ensure that your workforce is equipped to handle advanced technologies and keep pace with industry changes.

2. Consider adopting a modular manufacturing approach, which allows for flexibility and quick adaptation to changes in product demand or design.

Embracing these innovative solutions can help manufacturers stay competitive in an increasingly complex market.

Strategies for Efficient Supply Chain Management in Wire Harness Industry

Efficient supply chain management is crucial for the wire harness industry, characterized by its complex manufacturing processes and the need for high-quality standards. One of the key strategies is to establish strong relationships with suppliers. Building a reliable network of suppliers ensures timely delivery of raw materials and components, which is essential for maintaining production schedules. Engaging in regular communication and fostering collaboration can lead to more predictable lead times and better responsiveness to market demands.

Another effective strategy involves leveraging technology for enhanced visibility and tracking throughout the supply chain. Utilizing advanced software solutions allows manufacturers to monitor inventory levels, manage orders, and forecast demand with greater accuracy. This proactive approach helps in minimizing delays and reducing costs associated with excess inventory or stockouts. Additionally, implementing just-in-time (JIT) practices can improve efficiency by aligning production schedules closely with customer demand, thereby optimizing resource utilization and reducing waste. By focusing on these strategies, companies in the wire harness industry can navigate the challenges of manufacturing and supply chain management more effectively.

Wire Harness Manufacturing Efficiency Metrics

This chart illustrates the manufacturing efficiency metrics within the wire harness industry, focusing on key challenges such as Production Time, Defect Rate, and Component Availability over a quarterly basis.

Related Posts

-

Exploring Innovations in Wire Harness Manufacturing for the Future of Automotive Technology

-

Revolutionizing Wire Harness Manufacturing with Advanced Automation Technologies in 2024

-

Comparing Different Approaches to Wire Harness Manufacturing Techniques

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

How to Choose the Right Wire Harness Wire for Your Project

-

2025 Top 10 Cable and Wire Harness Innovations Driving Industry Growth