Transforming Electronics with Custom Wire Harness and Cable Assembly Solutions

The demand for custom wire harness and cable assembly solutions has surged significantly in recent years, driven by advancements in technology and the increasing complexity of electronic devices. According to a report by Research And Markets, the global wire harness market is projected to reach approximately USD 62 billion by 2025, growing at a CAGR of 4.7% from 2019 to 2025. This growth is primarily attributed to the escalating need for efficient and reliable connectivity in automotive, aerospace, and consumer electronics sectors. Moreover, the advent of the Internet of Things (IoT) has intensified this demand, as more interconnected devices necessitate bespoke wiring solutions that streamline installation and enhance performance. Consequently, companies are now focusing on developing tailored wire harness and cable assembly designs that not only meet industry standards but also optimize space and reduce weight, further driving innovation in the electronics sector.

The Importance of Custom Wire Harness in Modern Electronics

The importance of custom wire harnesses in modern electronics cannot be overstated, especially as we encounter increasingly complex systems in sectors such as automotive and aerospace. These custom solutions provide tailored wiring configurations that address specific design and functionality needs, thereby optimizing space, reducing weight, and enhancing performance. As the automotive industry transitions toward more electrification and integration of advanced technology, the role of custom wire harnesses becomes even more critical, particularly given the rising demand for features like high bandwidth and electromagnetic compatibility.

Recent advancements, such as the integration of fiber optics into automotive wiring harnesses, exemplify this trend. Fiber optics are becoming essential in meeting the lightweight demands of modern vehicles while significantly increasing data transmission capabilities. Such innovations, along with the move towards modular wiring systems, indicate a shift in how wiring harnesses are perceived and constructed—making them central to modern electronics design. Ultimately, the significance of custom wire harnesses reflects a broader transformation in the electronics landscape, where specificity and adaptability are key to staying ahead in a fast-evolving market.

Advantages of Tailored Cable Assembly Solutions for Enhanced Performance

The rapid evolution of electronics has made tailored cable assembly solutions increasingly vital for achieving optimal performance in various applications. Customized wire harnesses and cable assemblies enhance not only the functionality but also the reliability of electronic systems.

According to a report by Research and Markets, the global market for custom cable assembly is expected to reach $47.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.3%. This growth underscores the critical role that custom solutions play in meeting the specific demands of modern electronic devices.

One significant advantage of tailored cable assemblies is their ability to optimize space and reduce weight, essential factors in industries like aerospace and automotive. Custom solutions are designed to meet the precise specifications of equipment, allowing for more efficient layouts that minimize bulk.

The same industry report notes that reducing the weight of wiring and harnessing can lead to improvements in overall energy efficiency, which is especially crucial as manufacturers strive to meet stricter environmental regulations. By investing in bespoke cable assemblies, companies can achieve better performance, greater durability, and improved compliance with industry standards, ensuring they remain competitive in a rapidly advancing market.

How Custom Solutions Improve Reliability and Efficiency in Electronics

Custom wire harness and cable assembly solutions play a critical role in enhancing the reliability and efficiency of electronic devices. According to a report by MarketsandMarkets, the global wire harness market is projected to reach $200 billion by 2026, driven by the increasing demand for high-quality, reliable connections in various sectors, including automotive, aerospace, and consumer electronics. Custom solutions allow manufacturers to tailor their wiring systems to specific project requirements, ensuring optimal performance and reducing the risk of failures that can lead to costly downtime.

Moreover, utilizing custom wire harnesses can significantly improve the efficiency of the assembly process. A study from the Association for Manufacturing Technology highlights that companies that adopt custom assembly solutions experience a reduction in assembly time by up to 30%. This time savings is achieved through better design integration, enabling manufacturers to streamline production and minimize waste. With the added benefits of enhanced durability and resistance to environmental factors, custom cable assemblies not only contribute to greater operational efficiency but also support the longevity and reliability of electronic products in an increasingly competitive market.

The Role of Custom Wire Harnessing in Reducing Manufacturing Costs

Custom wire harnessing plays a pivotal role in modern electronics manufacturing by streamlining production processes and significantly reducing costs. By designing wire harnesses tailored to specific applications, manufacturers can simplify assembly procedures, allowing for quicker installation and fewer errors. This tailored approach not only enhances efficiency but also minimizes the amount of wasted materials, further driving down manufacturing expenses.

Additionally, custom cable assemblies provide flexibility in design, enabling manufacturers to adapt to varying production demands without incurring significant redesign costs. Standardization of components across multiple harnesses can also lead to bulk purchasing advantages, which can be leveraged to negotiate better pricing with suppliers. Ultimately, the integration of custom wire harness solutions fosters an environment of innovation while promoting cost-effectiveness, making it an essential strategy for companies looking to remain competitive in a rapidly evolving electronics market.

Innovative Trends in Wire Harness Design for Next-Generation Electronics

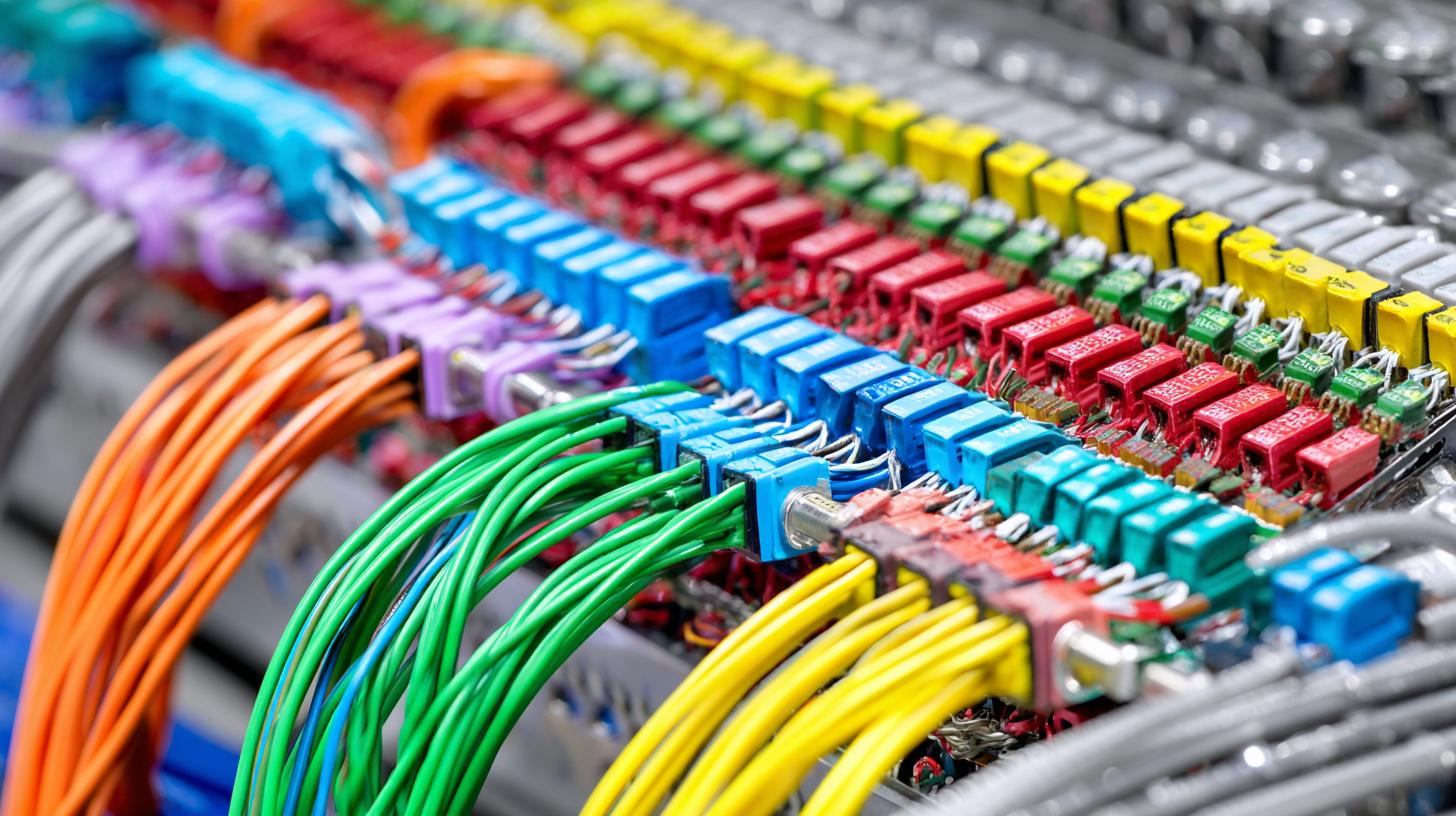

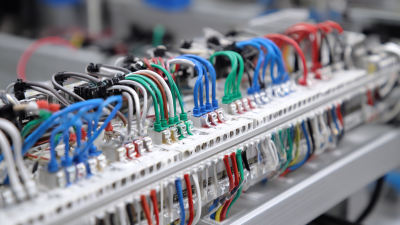

The landscape of electronics is rapidly evolving, driven by the increasing demand for innovation and efficiency in design. As we move towards next-generation electronics, wire harness design is emerging as a critical element in achieving streamlined functionality and enhanced performance. Modern wire harnesses are not just simple connectors; they are intricate systems that play a pivotal role in reducing weight, minimizing space, and improving electrical integrity in devices.

Innovative trends in wire harness design focus on customization and adaptability, enabling engineers to meet the specific needs of diverse applications. This includes the use of advanced materials and manufacturing techniques, such as 3D printing and automated assembly, which allow for more complex geometries and tighter tolerances. Additionally, the integration of smart technology, like sensors and connectors with built-in diagnostics, is paving the way for smarter and more reliable wiring solutions. As electronics continue to advance, embracing these innovative trends will be essential for creating the high-performance devices of the future.

Related Posts

-

Ultimate Guide to Sourcing the Best Wire Harness Cables: Tips, Trends, and Market Insights for Global Buyers

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production

-

Innovative Solutions for Wire Harness and Cable Assembly in Modern Manufacturing

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

7 Best Wire Harness Cable Innovations Revolutionizing Industry Standards

-

What is the Importance of Cable Wire Harness Assembly in Modern Electronics