What is Wire Harness Assembly and Its Impact on Electronics Industry Efficiency

Wire harness assembly plays a pivotal role in enhancing the efficiency of the electronics industry, serving as the backbone for electrical distribution in numerous applications. According to a report by Grand View Research, the global wire harness market is projected to reach USD 275.5 billion by 2025, reflecting a compound annual growth rate of 4.4% from 2019. This growth underscores the increasing demand for wire harnesses across various sectors, including automotive, aerospace, and industrial machinery. The proper assembling of wire harnesses ensures that electronic systems are reliable, effective, and safe, directly impacting the operational efficiency and performance of end products. As manufacturers strive for greater automation and precision in their processes, understanding the nuances of wire harness assembly becomes essential for optimizing workflows and driving innovation in the electronics sector.

Understanding Wire Harness Assembly: Basics and Components

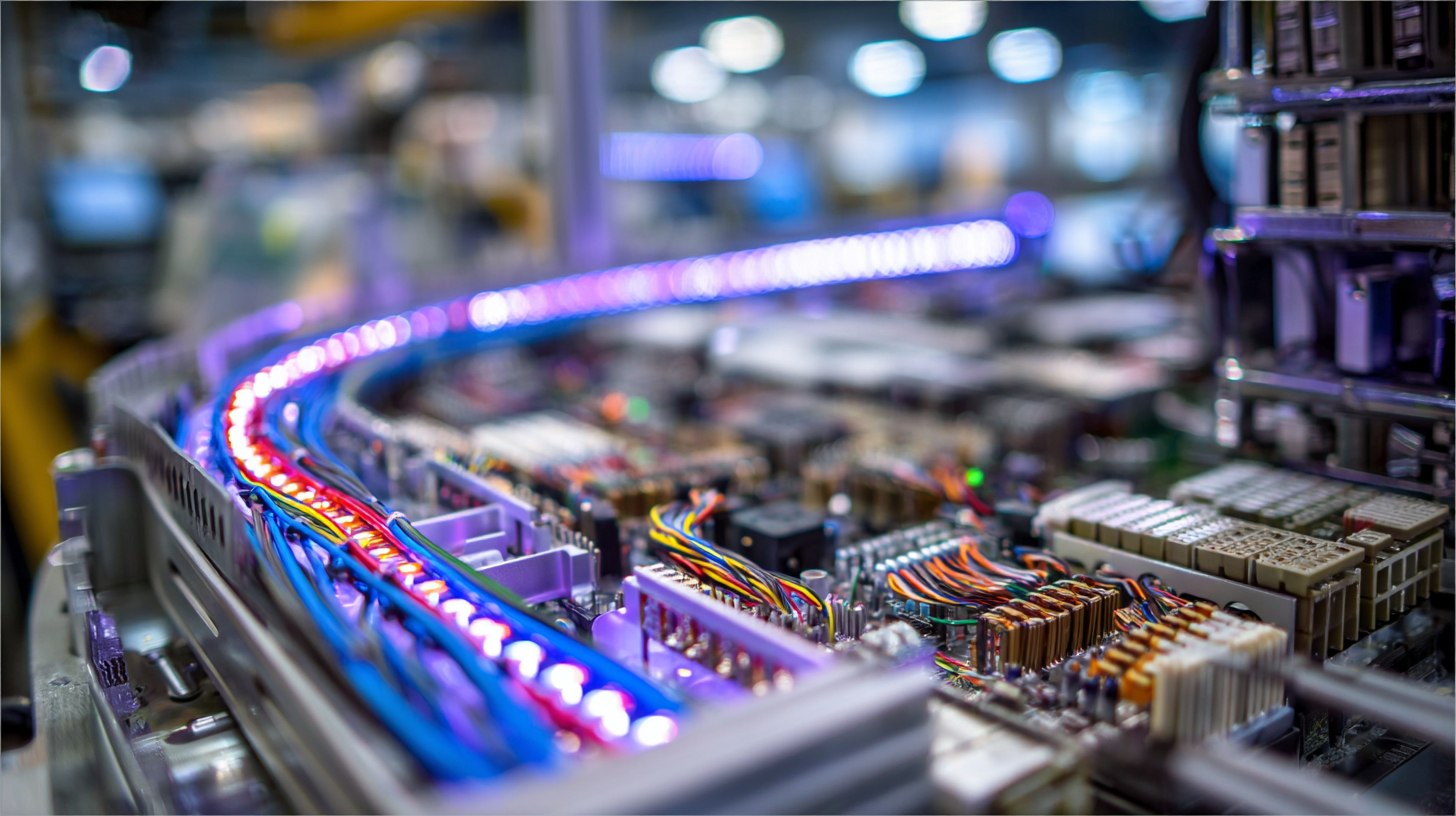

Wire harness assembly plays a critical role in the electronics industry, providing a streamlined solution for connecting various components. Essentially, a wire harness is a structured set of wires, terminals, and connectors that facilitate electrical communication between different parts of an electronic device. Understanding its basic components, such as wires, connectors, and protective coverings, is crucial for anyone involved in the design or production of electronic products.

When assembling wire harnesses, attention to detail is paramount. One key tip is to ensure that the wire lengths are precisely measured to avoid excess slack or tension, which can cause damage over time. Another important aspect is selecting the right type of connectors for the application to ensure optimal conductivity and durability. Proper insulation should also be prioritized to protect against potential short circuits and environmental factors.

Moreover, the organization of wiring within a harness can greatly influence efficiency during installation. Using color-coded wires or labeled connectors can help reduce assembly time and minimize errors. By focusing on these basics and best practices, manufacturers can enhance the overall efficiency and reliability of their electronic devices, ultimately impacting the industry's success.

Key Steps in the Wire Harness Assembly Process for Optimal Performance

Wire harness assembly is a crucial process in the production of electronic products, impacting the overall efficiency of the electronics industry. The assembly involves several key steps that ensure optimal performance of the final product. Initially, precise planning and design are essential. This stage includes determining the wire types, lengths, and connectors required for the specific application. Attention to detail at this phase can prevent costly mistakes later in the production process.

Tip: Always create a detailed blueprint before starting the assembly to streamline the process and minimize errors.

Following the planning stage, the next step is cutting and stripping the wires to the required lengths. This task demands accuracy and consistency, as improperly cut wires can lead to functional issues in the end product. After preparing the wires, assembly of connectors and terminals comes into play. Correctly attaching these components is critical for ensuring reliable electrical connections.

Tip: Use high-quality tools and equipment during assembly to maintain safety and improve efficiency in operations.

Finally, the assembly is tested for functionality and quality assurance before being integrated into the final electronic device. Implementing a robust testing process can significantly reduce the risk of failure, boosting both the reliability of the product and the overall efficiency of the production line.

The Role of Wire Harness Assemblies in Enhancing Electronics Efficiency

Wire harness assemblies play a pivotal role in enhancing the efficiency of the electronics industry by streamlining connections and reducing installation times. According to a report by MarketsandMarkets, the global wire harness market is projected to reach USD 87.1 billion by 2025, reflecting a robust annual growth rate driven by the increasing complexity of electronic devices. These assemblies reduce the chances of errors during the manufacturing process, resulting in improved product reliability and reduced production costs.

Furthermore, the integration of advanced technologies in wire harness design, such as computer-aided design (CAD) and automated assembly processes, significantly contributes to operational efficiency. A study by Allied Market Research indicates that the use of automation in wire harness production can increase labor productivity by up to 30%. By minimizing manual handling and errors, manufacturers can focus on innovation and quality, leading to a more sustainable and efficient electronics sector. As industries continue to evolve, the optimization of wire harness assemblies will remain crucial in meeting the demands of modern electronics.

Impact of Wire Harness Assembly on Electronics Industry Efficiency

Challenges in Wire Harness Assembly and Solutions for Improvement

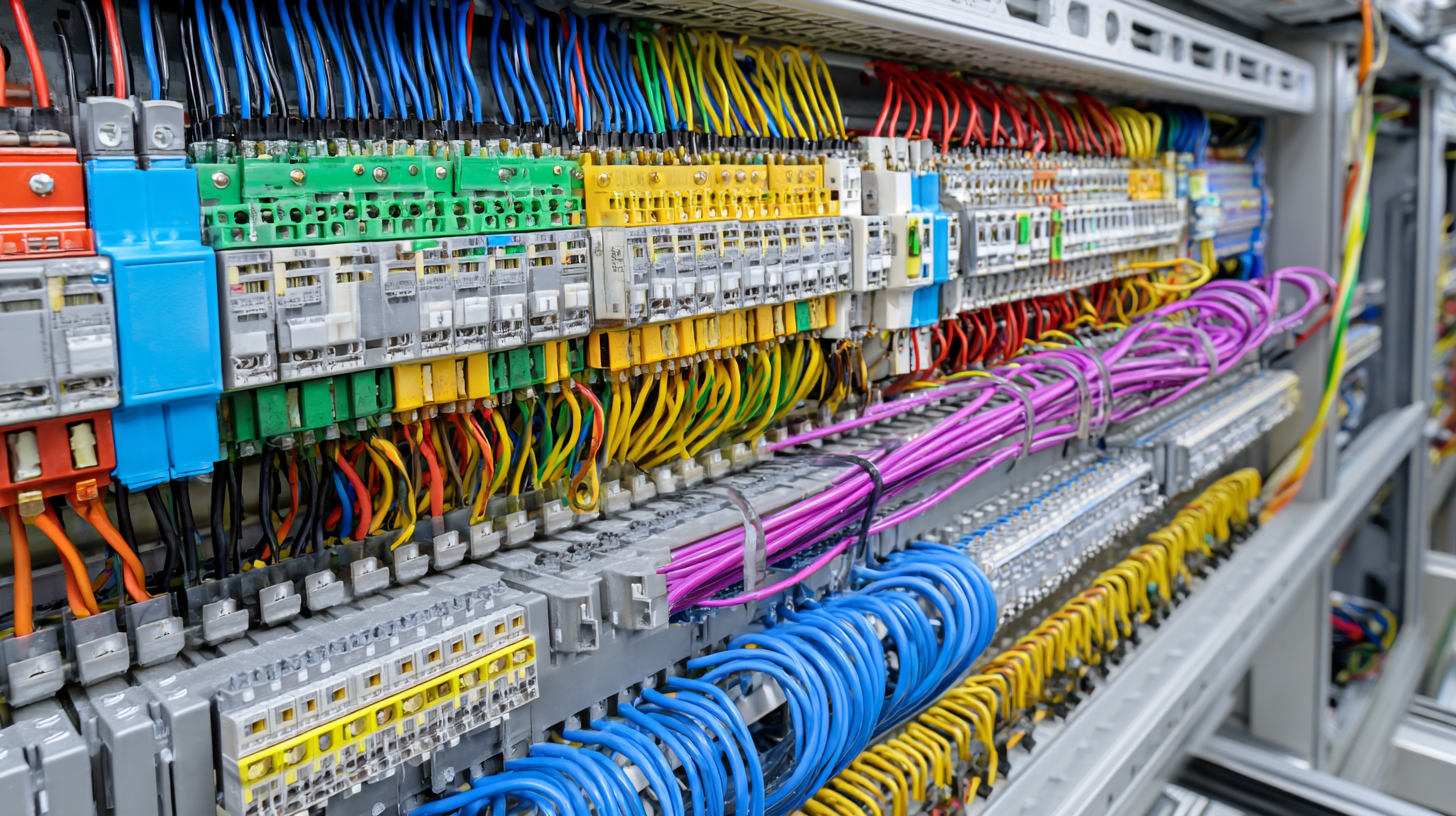

Wire harness assembly plays a crucial role in the efficiency of the electronics industry, but it also presents several challenges that impact production timelines and quality. One major issue is the complexity of modern electronic devices, which often require intricate wiring setups. This complexity can lead to increased assembly time and a greater likelihood of errors, such as miswiring or poor connections. Furthermore, managing inventory for the various components needed can complicate logistics, leading to delays that affect overall productivity.

To address these challenges, companies are increasingly adopting automation and advanced manufacturing technologies. Implementing automated assembly lines can significantly reduce human error and improve speed. Additionally, utilizing software for better inventory management ensures that the necessary components are readily available, minimizing downtime. Training workers in specialized skills and employing modular wiring solutions also contribute to more efficient assembly processes. As these strategies become more commonplace, the electronics industry is expected to see improved efficiency and a reduction in the challenges associated with wire harness assembly.

What is Wire Harness Assembly and Its Impact on Electronics Industry Efficiency

| Aspect | Details |

|---|---|

| Definition | Wire harness assembly is a collection of wires, connectors, and terminals that transmit electrical signals and power within electronic systems. |

| Industry Impact | Improves overall efficiency by streamlining electrical connections and reducing installation time in electronic devices. |

| Common Challenges | Complexity in design, difficulty in quality control, and integration issues with different components. |

| Solutions for Improvement | Implementing better design tools, automated assembly techniques, and rigorous testing protocols. |

| Technological Advances | Use of AI and IoT in monitoring assembly processes and improving precision and efficiency. |

| Future Trends | Shift towards more integrated, modular designs along with increased use of sustainable materials. |

Future Trends in Wire Harness Technology and Its Impact on the Industry

The wire harness assembly is undergoing transformative changes that are set to redefine efficiency within the electronics industry. As industries increasingly lean towards automation and connectivity, advancements in wire harness technology become essential. Emerging trends, such as the integration of smart wiring solutions and the use of lightweight materials, are paving the way for enhanced performance and durability. These innovations not only reduce the overall weight of electronic devices but also improve their energy efficiency, making devices more sustainable and cost-effective over their lifecycles.

Another significant trend is the rise of customization in wire harness assembly to meet the specific demands of various applications. As manufacturers adopt more flexible production methods, they are better equipped to cater to the unique needs of different sectors, including automotive, consumer electronics, and industrial machinery. This shift towards modular designs allows for quicker assembly times and reduced waste, ultimately boosting productivity. Additionally, the incorporation of advanced manufacturing technologies, such as 3D printing and AI-driven quality control, enhances precision while minimizing errors during the assembly process, which is critical for high-stakes industries where reliability is paramount.

Related Posts

-

Exploring the Unique Features and Applications of the Best Wire Harness Assemblies Worldwide

-

Ultimate Guide to Sourcing the Best Wire Harness Cables: Tips, Trends, and Market Insights for Global Buyers

-

How to Choose the Best Wire Harness Wire for Future Tech Trends in 2025

-

Global Sourcing of Premium Electronic Wire Harnesses: China's Quality Leads the Way

-

The Future of Harness Assembly Driven by Innovation and Global Demand

-

Top Strategies for Enhancing Efficiency in Cable and Wire Harness Production