Top 10 Wire Harness Manufacturing Techniques for Efficient Production

In the ever-evolving landscape of wire harness manufacturing, efficiency and precision are paramount. Renowned industry expert John Smith, a leading figure in wire harness production, once stated, "The future of wire harness manufacturing lies in optimizing processes and embracing innovative techniques that enhance productivity." As businesses strive to meet the growing demands for high-quality electrical components, the adoption of advanced manufacturing techniques becomes critical.

The art of wire harness manufacturing encompasses a variety of approaches designed to streamline production while ensuring the utmost reliability and safety of the end products. Techniques such as automated assembly, advanced materials selection, and precision testing play a vital role in minimizing waste and maximizing output. In this rapidly advancing industry, staying ahead of the curve means continually refining these techniques and leveraging new technologies to meet consumer expectations and regulatory requirements.

This article delves into the top ten manufacturing techniques that are revolutionizing wire harness production. By exploring these methods, manufacturers can enhance their operational efficiency and ultimately contribute to the success of a wide range of industries that rely on sophisticated electrical systems.

Overview of Wire Harness Manufacturing Techniques

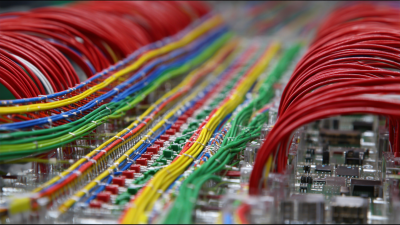

Wire harness manufacturing is a critical process in various industries, including automotive, aerospace, and electronics. Efficient production of wire harnesses relies on several key techniques that streamline assembly and ensure high quality. One fundamental approach is modular assembly, which breaks down the manufacturing process into smaller, manageable sections. This method allows for parallel processing, where multiple components can be worked on simultaneously, significantly speeding up overall production time.

Another essential technique is the use of advanced automated tools and machinery, which can enhance precision and reduce human error. Automated cutting, stripping, and crimping machines are commonly integrated into production lines to facilitate consistent results and minimize waste. Moreover, the application of lean manufacturing principles helps eliminate unnecessary steps and optimize workflows, leading to a more productive and cost-effective harness assembly process. By focusing on these techniques, manufacturers can achieve higher efficiency and improve the quality of their wire harnesses.

Top 10 Wire Harness Manufacturing Techniques for Efficient Production

| Technique | Description | Advantages | Applications |

|---|---|---|---|

| Automated Cutting | Precision wire cutting using automated machines. | Increased accuracy and reduced waste. | Automotive wiring systems |

| Crimping | Joining wires and terminals using mechanical force. | Strong, reliable connections. | Electronics and appliances |

| Wire Assembly | Combining wires into a harness structure. | Organized and efficient wiring. | HVAC systems |

| Soldering | Joining wires using melted solder. | Excellent electrical conductivity. | Consumer electronics |

| Wire Stripping | Removing insulation from wires. | Prepares wires for connections. | Industrial machinery |

| Cable Management | Organizing and bundling wires. | Reduces clutter and simplifies maintenance. | Telecommunications |

| Quality Control | Inspections and testing during production. | Ensures reliability and safety. | All wire harness applications |

| Environmental Protection | Components designed for durability against elements. | Increases longevity of harnesses. | Automotive and outdoor equipment |

| Rapid Prototyping | Quick manufacturing of wire harness prototypes. | Speeds up the design process. | New product development |

| Flexible Manufacturing Systems | Automation systems adaptable for various products. | Increases production efficiency. | Large scale manufacturing |

Importance of Efficient Production in Wire Harness Manufacturing

Efficient production in wire harness manufacturing is crucial for several reasons, particularly in an era where demand for high-quality components is on the rise. Efficient processes not only reduce manufacturing costs but also contribute to faster turnaround times. In a competitive market, companies that optimize their production techniques can achieve significant advantages, ensuring they meet customer expectations without extensive delays. Furthermore, improved efficiency can minimize waste and enhance resource management, leading to more sustainable practices within the industry.

Another significant aspect of efficient production is its impact on product quality and reliability. When manufacturing processes are streamlined, there is a greater consistency in the assembly of wire harnesses, which translates into more reliable end products. This not only fosters customer trust but also reduces the likelihood of defects and costly recalls. By focusing on efficient production techniques, manufacturers can ensure that they are not only responding to immediate market demands but are also positioning themselves for long-term success in a rapidly evolving technological landscape.

Key Techniques for Enhancing Wire Harness Production Efficiency

Enhancing wire harness production efficiency requires a thorough understanding of key techniques that streamline the manufacturing process. One vital approach is the implementation of automated assembly systems. These systems can significantly reduce manual labor and improve accuracy by utilizing robotic technology for tasks such as cutting, stripping, and crimping wires. This not only speeds up production but also minimizes human error, resulting in higher quality products.

Another important technique is the optimization of inventory management through just-in-time (JIT) practices. By closely monitoring material requirements and coordinating with suppliers, manufacturers can reduce excess inventory and ensure that the right components are available when needed. This lean approach helps to minimize waste and lowers storage costs, ultimately enhancing overall production efficiency. Additionally, investing in training and skill development for workers can lead to more efficient processes, as experienced personnel are better equipped to identify and solve problems quickly, thereby maintaining a smooth workflow.

Innovative Technologies in Wire Harness Assembly Processes

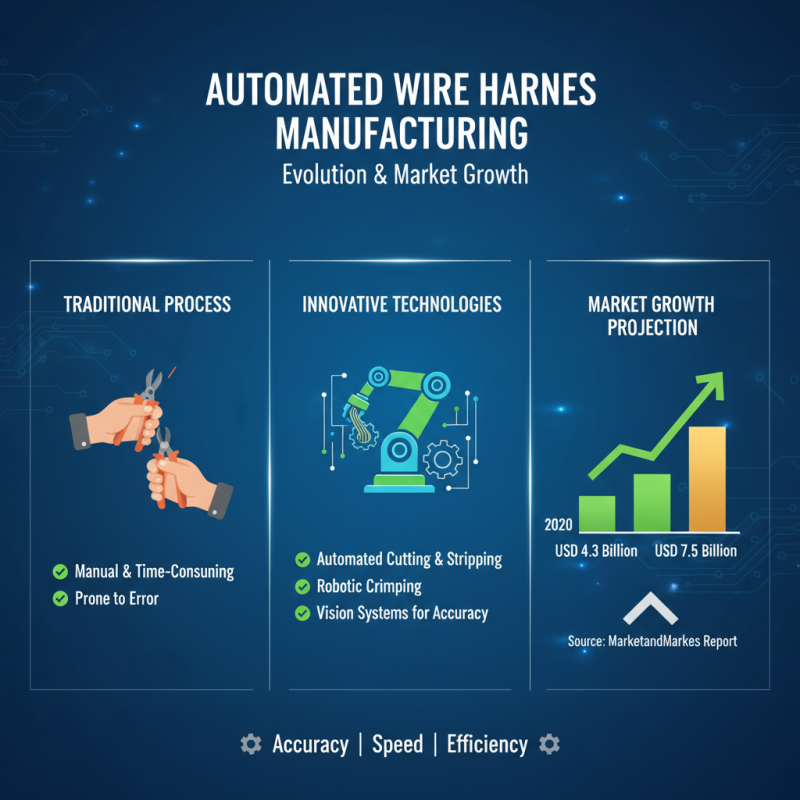

The landscape of wire harness manufacturing has evolved significantly with the advent of innovative technologies aimed at enhancing assembly processes. One of the prominent advancements in this field is the use of automated systems for wire cutting, stripping, and crimping. According to a report by MarketsandMarkets, the global market for automated wire harness manufacturing is projected to grow from USD 4.3 billion in 2020 to USD 7.5 billion by 2025, highlighting the increasing reliance on automation to improve accuracy and reduce production time.

In addition to automation, advancements in software solutions for design and assembly are playing a crucial role in optimizing wire harness production. Technologies such as Computer-Aided Design (CAD) and simulation software allow manufacturers to create complex wire harness systems with high precision. A survey conducted by COTS Journal indicated that companies implementing such technologies experienced a 30% reduction in design errors and a significant improvement in lead times. Furthermore, the integration of data analytics into production processes enables real-time monitoring and predictive maintenance, ensuring higher efficiency and lower operational costs.

The shift towards these innovative strategies not only enhances productivity but also ensures quality control throughout the manufacturing process. As manufacturers increasingly adopt these advanced assembly technologies, the wire harness industry is poised for rapid growth, driven by the demands of the automotive, aerospace, and electronics sectors. According to a recent analysis, the automotive industry alone is expected to contribute to over 50% of the wire harness market growth by 2026, demonstrating the critical role of innovative technologies in shaping the future of manufacturing in this domain.

Quality Control Measures in Wire Harness Production Techniques

Quality control in wire harness production is paramount to ensure reliability and performance in various applications, particularly in the automotive and aerospace industries. According to a report by MarketsandMarkets, the global wire harness market is projected to reach $70.83 billion by 2025, underscoring the critical need for top-tier manufacturing techniques that adhere to stringent quality standards. Implementing rigorous inspection protocols at every stage of production, from raw material selection to final assembly, helps identify and mitigate defects early, significantly reducing warranty claims and enhancing customer satisfaction.

To bolster quality control measures, manufacturers are increasingly adopting automated inspection technologies. For instance, the implementation of machine vision systems can facilitate real-time monitoring of wire harness assemblies, providing precise measurements and defect detection. A study published in the Journal of Manufacturing Processes highlighted that the use of automated quality assurance methods could reduce defects by as much as 40%, leading to substantial cost savings and improved productivity. Additionally, establishing a robust traceability system allows for tracking components throughout the production process, ensuring that any issues can be swiftly addressed while maintaining compliance with industry standards and regulations.

Top 10 Wire Harness Manufacturing Techniques for Efficient Production

Related Posts

-

7 Best Wire Harness Cable Innovations Revolutionizing Industry Standards

-

The Future of Best Wire Harness Cable Assembly in the Evolving Global Market

-

Comparing Different Approaches to Wire Harness Manufacturing Techniques

-

Global Sourcing of Premium Electronic Wire Harnesses: China's Quality Leads the Way

-

How to Choose the Right Cable Assembly Wire Harness for Your Project

-

2025 Guide on How to Choose the Right Harness Cable Assembly for Your Needs